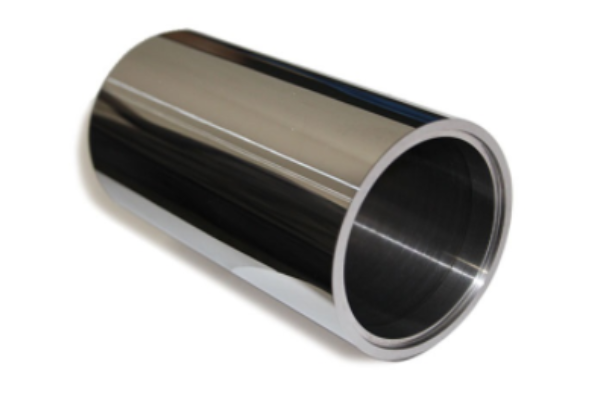

Factory Supply Tungsten Carbide Sleeves For Slurry Pump With High Precision

Description

Tungsten carbide as a material for the slurry pump shaft sleeve , It is characterized by its excellent high temperature strength, excellent oxidation and thermal corrosion resistance, good fatigue properties as well as a high degree of fracture toughness.

Over 18 months of destructive field tests have proven the tungsten carbide bushings for slurry pumps have several times the service life of steel bushings. There is a reduction in total maintenance costs and downtime as a result. Using high density cemented carbide material, Zhuzhou Chuangrui shaft sleeves for slurry pumps are precisely formed, fired, and ground to size. Tungsten carbide materials (HRA89 to 92.5 hardness) resist this destructive action. In addition, the cemented carbide sleeve surface is highly polished, which combined with the lower coefficient of friction, results in extended sleeve life and long packing service.

Straight Sleeves

T Model Sleeves

Special Shaft Sleeves

Coating Carbide Bushing

Advantages Of Cemented Carbide Sleeve

Self-lubricating;Corrosion resistance

Wear-resistant and high-temperature resistant

Large bearing capacity

Trial order accept;Finished and blanks available

Various sizes and specifications can be processed according to customer requirements

Stable quality, good density and high comprehensive performance

Why can choose us when you need carbide sleeve:

Professional suggest

100% raw material

Full-set quality control

Strict quality inspection

Tight Tolerances

Technology Support

As international standard

Good quality and prompt delivery

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope