Tungsten Carbide Rods

Description

Tungsten carbide rods are widely used for high-quality solid carbide tools such as milling cutters, end mills, drills, reamers; stamping,measuring tools and various roll wear parts.

Specification Of Tungsten Carbide Rods

Types Of Carbide Rods:

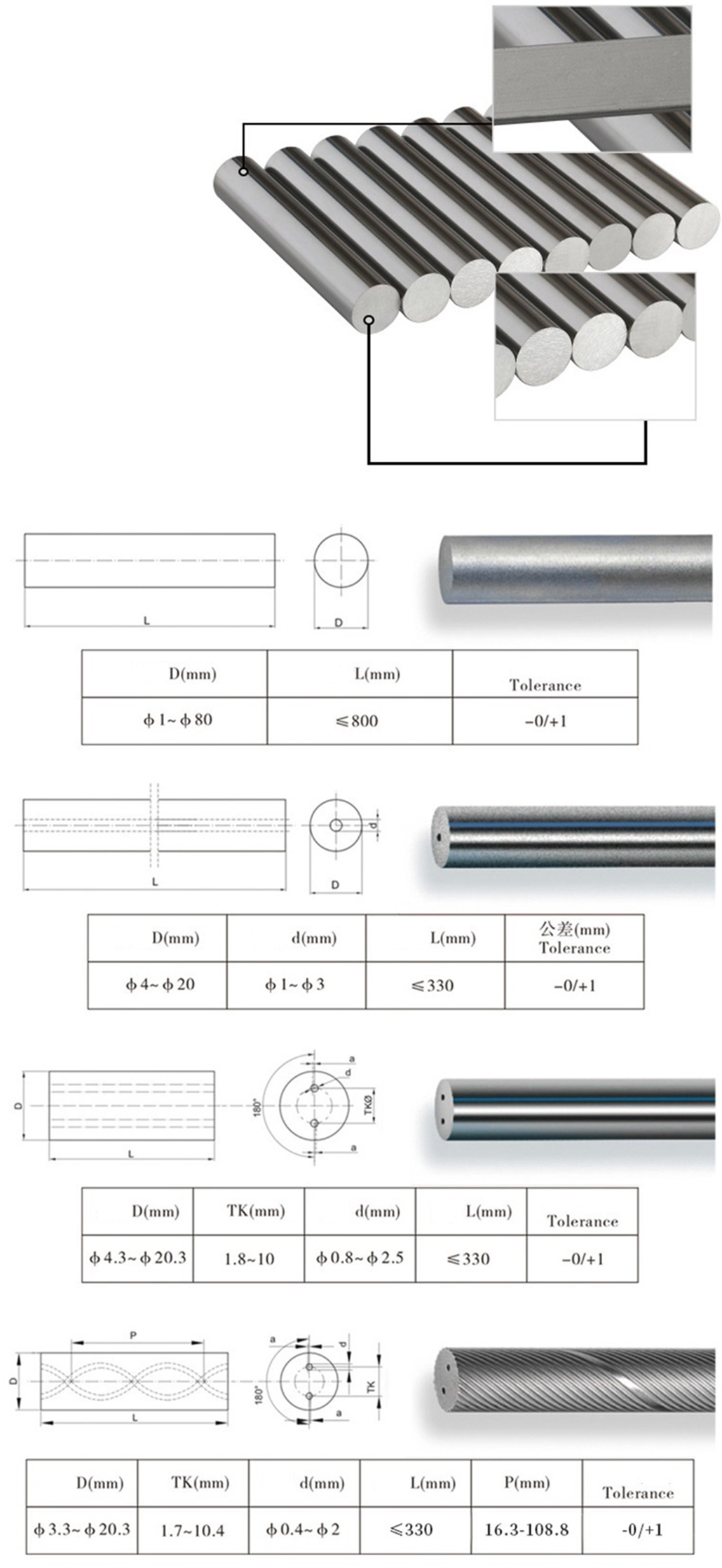

Solid Finished Carbide Rod & Carbide Rod Blank

Carbide Rod With Straight Central Coolant Holes

Carbide Rods With Two Straight Coolant Holes

Carbide Rods With Two Helical Coolant Holes.

Various Dimensions Is Available, Customization Services Are Acceptable

Grade

| ISO Grade | Grain Size (μm) | Co% | Hardness (HRA) | Density (g/cm3) | T.R.S (N/mm2) | Application Industries | Application |

| K05-K10 | 0.4 | 6.0 | 94 | 14.8 | 3800 | PCB Industry | Stainless steel,non-ferrous metal,composite material and PCB cutters |

| K10-K20 | 0.4 | 8.5 | 93.5 | 14.52 | 3800 | PCB Cutting Tools; Plastic And High Hardness Material | |

| K10-K20 | 0.2 | 9.0 | 93.8 | 14.5 | 4000 | Mold Industry | High Hardness Material |

| K20-K40 | 0.4 | 12.0 | 92.5 | 14.1 | 4200 | 3C And Mold Industry | Cutting Steel(HRC45-55)Al Alloy And Ti alloy |

| K20-K40 | 0.5 | 10.3 | 92.3 | 14.3 | 4200 | Steel Stainless And Heat Resistant Alloy,Cast Iron | |

| K20-K40 | 0.5 | 12.0 | 92 | 14.1 | 4200 | Steel Stainless,Cast Iron And High Hardness Material | |

| K20-K40 | 0.6 | 10.0 | 91.7 | 14.4 | 4000 | Steel Stainless And Heat Resistant Alloy,Cast Iron And General Steel | |

| K30-K40 | 0.6 | 13.5 | 90.5 | 14.08 | 4000 | Precision Stamping Dies | Making Round Punch |

| K30-K40 | 1.0-2.0 | 12.5 | 89.5 | 14.1 | 3600 | Making Flat Puch | |

| K30-K40 | 1.5-3.0 | 14.0 | 88.5 | 14 | 3700 |

Features

● 100% virgin tungsten carbide materials

● Unground and ground are both available

● Varied sizes and grades; Customization services

● Excellent wear resistance & durability

● Competitive prices

Cemented Carbide Rod For Cutting Tools

Finished Tungsten Steel Rods

Tungsten Carbide Round Bar

Cemented Carbide Micro Rod

Blank Tungsten Carbide Rod

Carbide Rod Manufacturer

Advantage

● Grain size from 0.2μm-0.8μm,hardness 91HRA-95HRA. With rigorous quality inspections and ensure consistent quality each batch.

● Specialized in carbide rod more than 10 years, with an outstanding product line of solid carbide rods and rod with coolant holes.

● As an ISO manufacturer, we use top-quality materials to guarantee the quality and good performance of our carbide rods.

● Carbide rod is raw material to make cutting tools. The tools made from us are with long lifetime and stable machining performance.

Application

Tungsten Carbide Rod Widely In Many Fields,Such As In The Paper, Packaging, Printing, And Non-ferrous Metal Processing Industries;Machinery, Chemical, Petroleum, Metallurgy, Mould Industry. And Automobile & Motorcycle Industry, Electronic Industry, Compressor Industry, Aerospace Industry, Defense Industries.

OUR QUALITY CONTROL

Quality Policy

Quality is the soul of products.

Strictly process control.

Zero tolerate of defects!

Passed ISO9001-2015 Certification

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope