tungsten carbide strips cutter for woodworking

Description

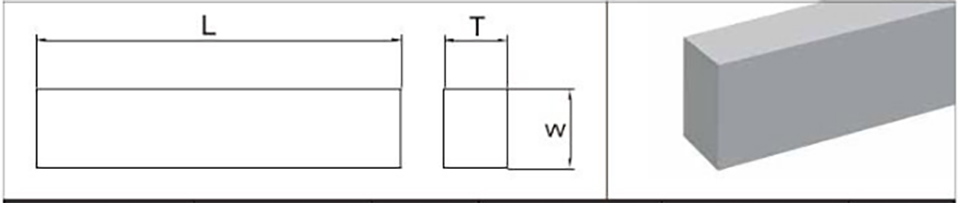

Tungsten carbide flat bars are mainly made from wolfram carbide and cobalt powder by powder metallurgy methods. The main production process of tungsten carbide bar stock is powder milling, ball milling, pressing and sintering. For different uses, the content of WC and Co in tungsten carbide square bar is not the same. Solid carbide rectangular bar is mainly used to process gray cast iron, non-ferrous metal materials, chilled cast iron, hardened steel, PCB, brake materials, etc. Carbide flat bar can be further processed at clients’ factory or workshop by wire cut, grinding, soldering.

Applications

1. Used to make wear-resistant tools. Such as woodworking industry knives, plastic crushing knives, etc.

2. Used to make high-temperature resistant parts, wear-resistant parts, anti-shielding parts. Such as the guide rail of the machine tool, the anti-theft reinforcement plate of the ATM machine, etc.

3. Used to make wear-resistant parts in the rubber and plastic industry.

4. Used to make molds.

5. The material properties of cemented carbide plates for different purposes are not consistent, and the appropriate material of cemented carbide plates should be selected according to the use when using.

Specifications

Common size as below:

|

Thickness |

Width |

Length |

Thickness |

Width |

Length |

||||

|

mm |

mm Tolerance |

mm |

mm Tolerance |

+1.5mm Tolerance |

mm |

mm Tolerance |

mm |

mm Tolerance |

+1.5mm Tolerance |

|

2 |

+0.3/0.1 |

3 |

+0.4/+0.2 |

310 |

3 |

+0.3/0.1 |

15 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

4 |

+0.4/+0.2 |

310 |

3 |

+0.3/0.1 |

16 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

5 |

+0.4/+0.2 |

310 |

3 |

+0.3/0.1 |

18 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

6 |

+0.4/+0.2 |

310 |

3 |

+0.3/0.1 |

20 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

8 |

+0.4/+0.2 |

310 |

3 |

+0.3/0.1 |

22 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

10 |

+0.4/+0.2 |

310 |

3 |

+0.3/0.1 |

25 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

12 |

+0.4/+0.2 |

310 |

3 |

+0.3/0.1 |

28 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

14 |

+0.4/+0.2 |

310 |

3 |

+0.3/0.1 |

31 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

15 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

5 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

16 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

6 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

18 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

8 |

+0.6/+0.2 |

310 |

|

2 |

+0.3/0.1 |

19 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

10 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

3 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

12 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

4 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

13 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

5 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

15 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

6 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

16 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

8 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

18 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

9 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

20 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

10 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

22 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

11 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

25 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

12 |

+0.4/+0.2 |

310 |

4 |

+0.3/0.1 |

30 |

+0.6/+0.2 |

310 |

|

3 |

+0.3/0.1 |

13 |

+0.4/+0.2 |

310 |

|||||

Advantages

Our tungsten carbide strip’s Advantages:

1. Superior heat stability.

2. Anti-deformation in high temperature.

3. Fine thermal shock resistance.

4. High thermal conductivity.

5. Excellent Oxidation control ability.

6. Strong anti-corrosion in high temperature.

7. Good corrosion resistance from Chemical.

8. High-wearing feature.

9. Long usage lifetime.

Package

Package of cemented carbide bars:

If you have any questions, welcome to contact us in anytime!

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope