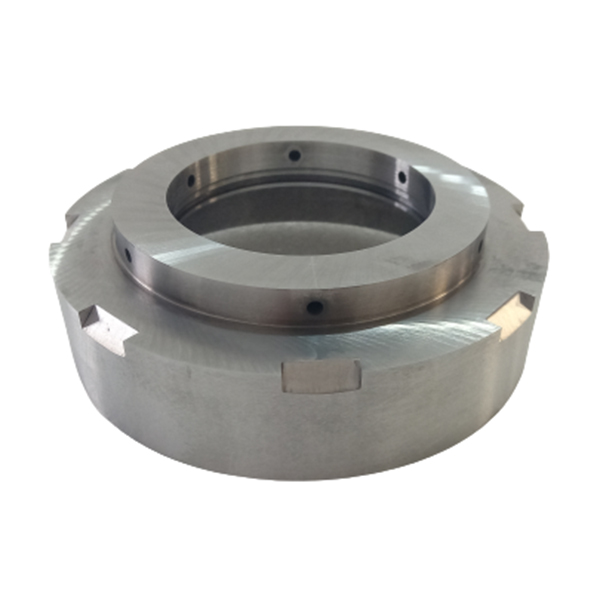

High Abrasive Resistant Carbide Tapered Bushings For Petrochemical Industry

Product Description:

Tungsten Carbide Bearing Bushings have the characters of high wear resistance, high corrosion resistance and good compressive properties.It's widely used in petrochemical industries and other industries which call for high properties of the bearing bushings or shaft sleeves.

Tungsten carbide sleeves is the basic material among the frictional materials. They are widely use as the basic components for sealing. And the sleeves are widely adopted in petrochemical industry due to its excellent performances such as wear ability, anti corrosion etc.

Carbide Bushing Sleeve Bearing Features:

● Use 100% tungsten carbide raw material

● Stable chemical properties

● Excellent performance and good wear / corrosion resistance

● HIP sintering, good compactness

● Strict products quality inspection

● Blanks, high machining accuracy / precision

● OEM customized sizes available

Tungsten carbide expansion cone common specifications:

|

Carbide Grade |

OD |

ID |

Height |

R° |

|

CR15 |

85 |

50 |

56 |

15 |

|

CR15 |

96 |

72 |

56 |

30 |

|

CR15 |

135 |

90 |

65 |

38 |

|

CR15 |

150 |

120 |

80 |

38 |

|

CR15 |

192 |

145 |

108 |

50 |

|

CR15 |

196 |

145 |

108 |

50 |

|

CR15 |

220 |

172 |

105 |

50 |

|

CR15 |

308 |

245 |

145 |

50 |

|

CR15 |

410 |

300 |

145 |

100 |

Specialty precision machining Manufactory!

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope