High Sealing Performance Tungsten Carbide Seal Ring For Mechanical Seals

Product Features

Tungsten carbide material is widely used as seal faces or rings with resistant-wearing,high fractural strength,high thermal conductivity, small heat expansion co-efficient.The tungsten carbide seal-ring can be divided into both of rotating seal-ring and static seal-ring.The two most common variations of Cemented carbide seal ring are cobalt binder and nickel binder.Tungsten carbide mechanical seals are being used increasingly on fluid pump to replace packed gland and lip seal. tungsten carbide mechanical seal Pump with mechanical seal perform more efficiently and generally perform more reliably for extended periods of time.

According to the shape, those seals are also called tungsten carbide mechanical seal rings. Due to the superiorities of tungsten carbide material, tungsten carbide mechanical seal rings shows high hardness, and the most important is that they resist corrosion and abrasion well. therefore, tungsten carbide mechanical seal rings are having wider use than seals of other materials.Tungsten carbide mechanical seal is provided to prevent pumped fluid from leaking out along the drive shaft. The controlled leakage path is between two flat surfaces associated with the rotating shaft and the housing respectively. The leakage path gap varies as the faces are subjected to varying external load which tend to move the faces relative to each other.The products require a different shaft housing design arrangement compared to that for the other type of mechanical seal because the mechanical seal is a more complicated arrangement and mechanical seal does not provide any support to the shaft.

Tungsten Carbide Mechanical Seal Rings Come In Two Primary Types

Cobalt bound (Ammonia applications should be avoided)

Nickel bound (May be used in Ammonia)

Typically 6% binder materials are used in tungsten carbide mechanical seal rings, although a wide range is available. Nickel-bonded tungsten carbide mechanical seal rings are more prevalent in the wastewater pump market due to their improved corrosion resistance compared with cobalt bound materials.

Tungsten Carbide Sealing Ring Application

Tungsten Carbide seal rings are widely used as seal faces in mechanical seals for pumps, compressors mixers and agitators found in oil refineries, petrochemical plants, fertilizer plants, breweries, mining , pulp mills, and the pharmaceutical industry. The seal-ring will be installed on the pump body and rotating axle, and forms through the end face of the rotating and static ring a liquid or gas seal.

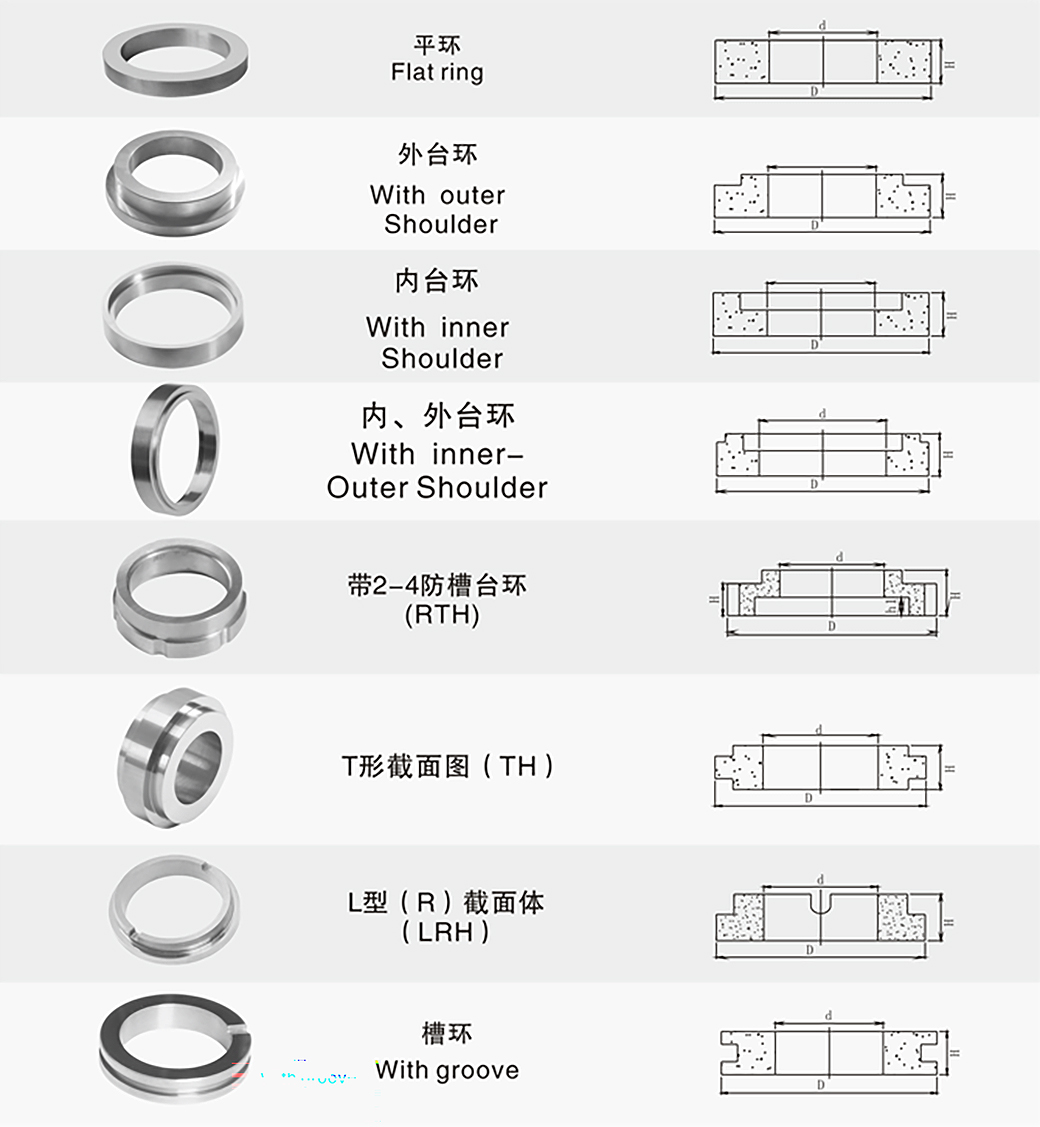

Tungsten Carbide Sealing Ring Shape For Reference

Tungsten Carbide Sealing Ring Dimensions

|

D(mm) |

d(mm) |

H(mm) |

|

10-500mm |

2-400mm |

1.5-300mm |

Material Grade Of Tungsten Carbide Sealing Ring

| Grades | Physical Properties | Major Application And Characteristics | ||

| Hardness | Density | TRS | ||

| HRA | G/cm3 | N/mm2 | ||

| CR40A | 90.5-91.5 | 14.50-14.70 | ≥2800 | It is suitable to produce seal ring and sleeve used in pumps industry due to high hardness and good wear-resistance, |

| CR06N | 90.2-91.2 | 14.80-15.00 | ≥2680 | It is suitable to produce sleeves and bushings used in pumps industry due to excellent corrosion & erosion resistance, |

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope