The planetary ball mills on the market are mainly made of the following materials: agate, ceramic, zirconia, stainless steel, tungsten carbide, nylon, PTFE, silicon nitride, etc

Tungsten carbide ball mill jar, also known as tungsten carbide ball mill jar, is a ball mill jar made of hard compound of refractory metal and bonded metal through powder metallurgy process, it has the advantages of high hardness, wear resistance, high strength, good toughness, heat resistance and corrosion resistance, and it can be used to grind cemented carbide powder, diamond, emery and other high hardness powders.

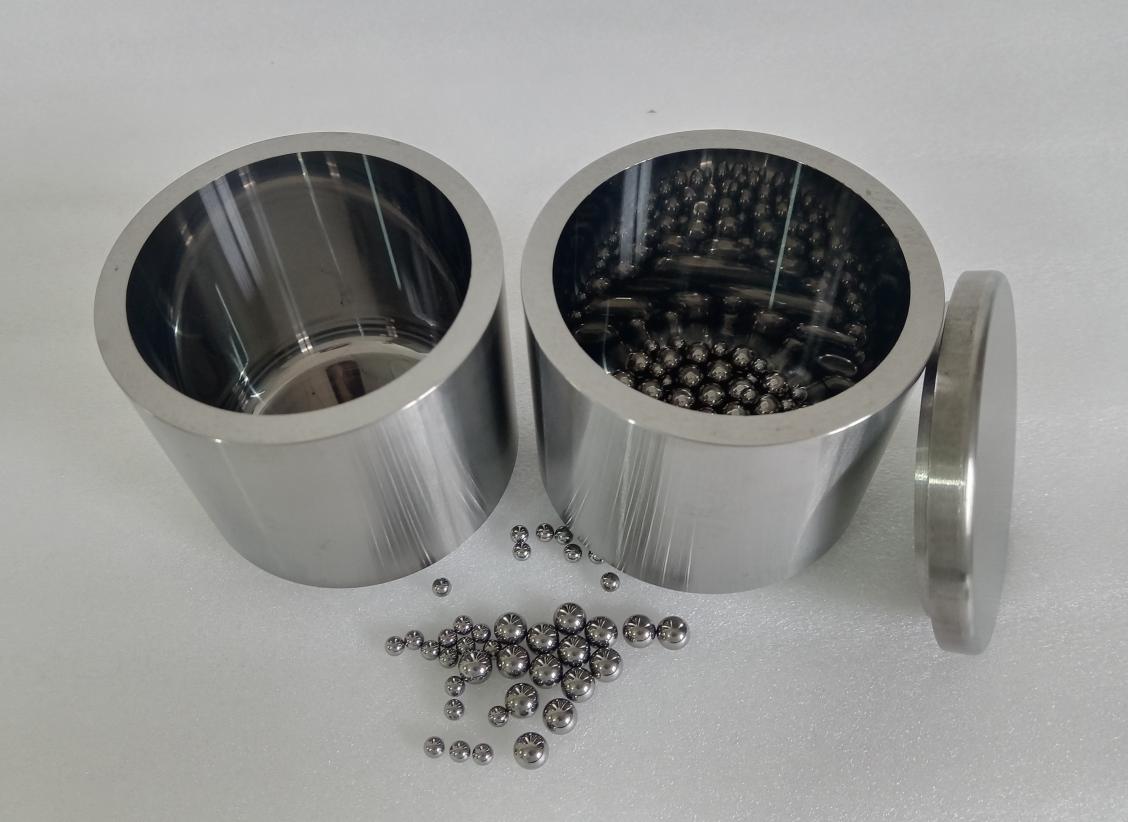

500ml tungsten carbide ball milling tank

Tungsten carbide ball mill tank, also known as tungsten carbide ball mill jar, is made of Wc and Co as the main components, sintered by powder metallurgy process at a high temperature of more than 1000 °C. It has the characteristics of high hardness, high wear resistance, acid and alkali resistance, high temperature oxidation resistance, specific gravity, no contaminant materials, strong crushing ability, etc., and can enter micron and even nanometer powder in a short time; it is suitable for ultra-fine grinding of metals (such as cemented carbide powder, diamond, emery) and non-metals (such as coal, coke, ore, rock, granular materials) and other minerals, strong acid and alkali and non-oxidizing materials of a certain hardness in the planetary ball mill, and is one of the main grinding tanks for high-energy ball milling, high-entropy alloy and mechanical alloying.

Zhuzhou Chuangrui Cemented Carbide Co., Ltd., as a professional manufacturer of tungsten carbide wear-resistant parts, we would like to introduce the characteristics of tungsten carbide grinding jars to you:

1)With independent design capabilities, we can recommend the appropriate size according to the application.

2)Between the bottom of the cavity, the top of the cavity and the side wall of the cavity of the ball mill tank, we designed a large R angle to avoid the dead angle of grinding.

3)The right angle between the cylinder, the top surface and between the cylinder and the bottom surface of the ball mill jar is eliminated.

4)When the blank is pressed, the mold is integrally formed, which can effectively avoid fracture during use.

5)carbide balls or zirconia balls can be choose.

6)Between the upper end face of the tank body and the cover surface of the tank, there is a rubber gasket sealing ring to eliminate the gap between the contact surfaces and prevent the leakage of substances in the tank.

7)0.05L/0.1L/0.25L/0.5L have blank stock, and the fastest delivery time can reach 7-10 days

8) The dimensions can be customized to meet the requirements, such as adding positioning steps, thickening or thinning the wall thickness of the tank, expanding the volume, and laser marking.

The tungsten carbide ball grinding jars on the market are uneven, so please pay attention to the selection from belowing aspects:

1)Preferred to choose manufacturer to eliminate intermediate price differences.

2)It is recommended to use virgin tungsten carbide powder and cobalt powder to produce tungsten carbide jars, which can effectively avoid defects such as dirty holes, scratches, abrasions, lack of materials, distortion and deformation, pitting, burrs, cracks and other defects in the jar.

For more information, please feel free to contact us at any time!

Post time: Jan-24-2024