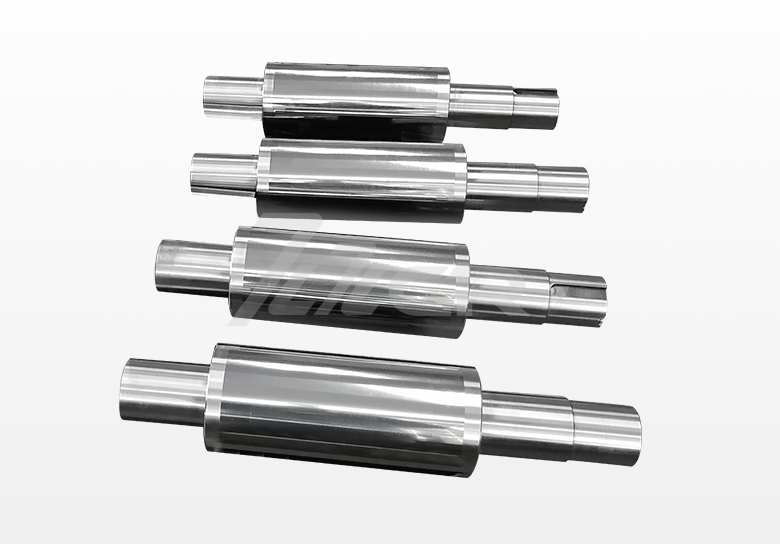

From the perspective of material composition, cemented carbide rolls are mainly prepared by powder metallurgy process by powder metallurgy process by using refractory metal compounds (such as tungsten carbide WC, titanium carbide TiC, etc.) as the matrix, and transition metals (such as cobalt Co, nickel Ni, etc.) as the binder phase. This special combination of materials gives tungsten carbide rolls a high degree of hardness, wear resistance and thermal fatigue resistance, enabling them to withstand the intense wear and tear of high-temperature, high-pressure and high-speed rolling processes. The ceramic roll is based on the ceramic material and processed by a special process. The ceramic material itself has extremely high hardness and excellent corrosion resistance, which makes the ceramic roll perform well in the rolling process, especially in the case of high requirements for the surface finish and corrosion resistance of the roll.

In terms of performance characteristics, tungsten carbide rolls are known for their wear resistance and thermal fatigue resistance. It has high hardness and good thermal stability, and can run stably for a long time in a high-temperature and high-load rolling environment, which greatly improves the operation efficiency of the rolling mill. In addition, tungsten carbide rolls also have good thermal conductivity, which can quickly dissipate the heat generated during the rolling process, reduce the surface temperature of the rolls, and reduce the damage of thermal stress to the rolls. Ceramic rolls, on the other hand, are characterized by their high hardness, corrosion resistance and high temperature stability. The special properties of ceramic materials make ceramic rolls not easy to be eroded by chemicals during the rolling process, and can maintain the finish and accuracy of the roll surface for a long time. At the same time, ceramic rolls can maintain stable performance in high-temperature environments, and will not deform or soften due to temperature increases.

In terms of application, cemented carbide rolls are widely used in the rolling production of steel, non-ferrous metals, alloy materials and other industries because of their excellent properties. Especially in high-strength, high-load rolling environments such as high-speed wire rod rolling mills and finishing rolling mills, cemented carbide rolls play an irreplaceable role. Ceramic rolls are widely used in hot and cold rolling production lines in the steel industry, ceramic production, glass processing and electronics industry because of their high hardness, corrosion resistance and high temperature stability.

Post time: Sep-02-2024