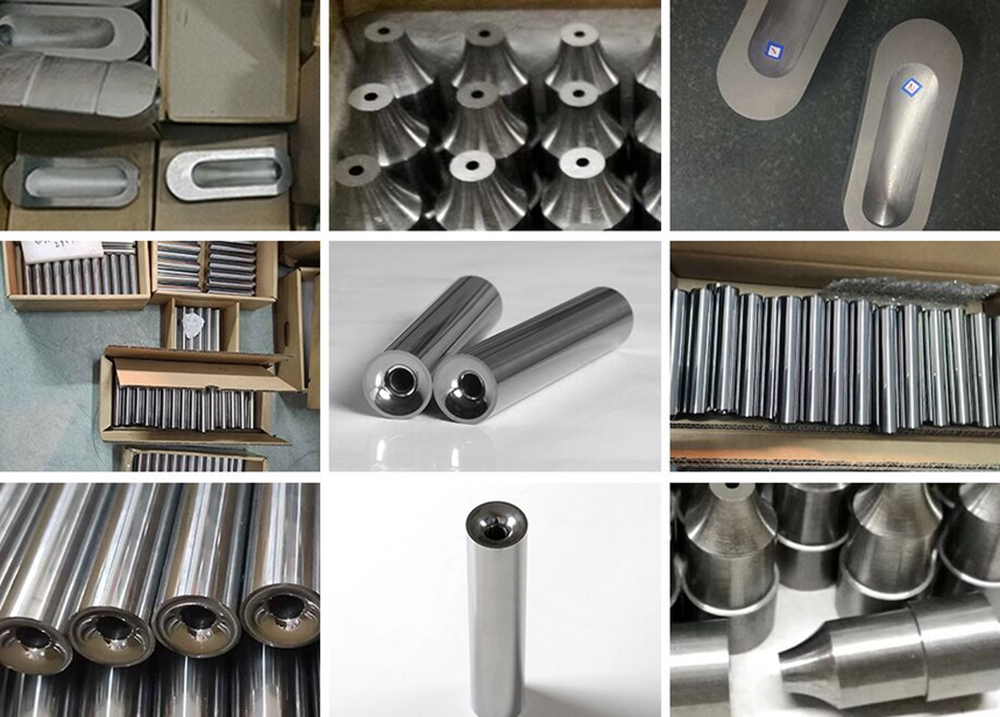

We often see a very small part in the manufacturing industry - the nozzle, although small, its role is that we cannot ignore. Industrial nozzles are generally used in various spraying, spraying, oil spraying, sandblasting, spraying and other equipment, and play a very important role. Of course, the material of the nozzle includes many kinds, such as cast iron, ceramic, tungsten carbide, silicon carbide, boron carbide, etc. Carbide nozzles are widely used in surface treatment, petroleum, chemical and other industries because of their advantages of corrosion resistance, long service life, excellent performance, high cost performance, and not easy to wear. Today, the editor of Chuangrui will introduce to you the common uses of cemented carbide nozzles.

Carbide for sandblasting

Carbide nozzles are an essential part of sandblasting equipment. The sandblasting equipment is powered by compressed air, and sprays the material to the surface of the workpiece at a high speed through a high-speed jet to achieve the purpose of surface treatment. Compared with nozzles made of other materials, such as steel nozzles, carbide nozzles have higher hardness, strength, wear resistance and corrosion resistance, and can better meet the needs of application conditions.

Carbide nozzles for oil drilling

In the process of oil drilling, it is generally in a relatively harsh environment, so the nozzle needs to withstand the high-speed impact of high-pressure abrasives during the working process, which is more prone to wear and failure. Ordinary materials are prone to thermal deformation or cracking, and nozzles need to be replaced frequently, which reduces work efficiency. Carbide nozzles can better improve this situation because of their high hardness, high strength and excellent wear and corrosion resistance.

Carbide Nozzle for CWS

When the coal-water slurry nozzle is working, it is mainly subjected to the low-angle erosion of the coal-water slurry, and the wear mechanism is mainly plastic deformation and micro-cutting. Compared with CWS nozzles made of other metal materials, cemented carbide nozzles have better wear resistance and corrosion resistance and have a longer service life (usually more than 1000h). However, cemented carbide itself is brittle, its hardness, toughness and thermal shock resistance are lower than other metal materials, it is not easy to process, and it is not suitable for making nozzles with complex shape and structure.

Carbide Atomizing Nozzle

The atomization forms of cemented carbide atomizing nozzles can be divided into pressure atomization, rotary atomization, electrostatic atomization, ultrasonic atomization and bubble atomization. Compared with other types of nozzles, cemented carbide nozzles can achieve the spray effect without an air compressor. The shape of the atomization is generally circular or fan-shaped, with good atomization effect and wide coverage. It is used in agricultural production spraying and industrial spraying. It is widely used in spraying, dust removal and humidification in manufacturing.

Chuangrui has independently developed a variety of material grades to improve the wear resistance and erosion resistance of materials, and provide customers with various types of nozzles with high quality and cost advantages to cope with different working conditions. It has mature and advanced production technology in cemented carbide production, matching automatic and semi-automatic production lines. If you have relevant needs, please feel free to contact us.

Post time: May-31-2023