Because of its unique high hardness and strong wear resistance, cemented carbide is widely used in industry and is known as industrial teeth. However, cemented carbide products are also prone to bending and deformation during processing. Today, we will analyze the reasons for the bending deformation of cemented carbide products, and find out the measures that can be prevented from the deformation of parts.

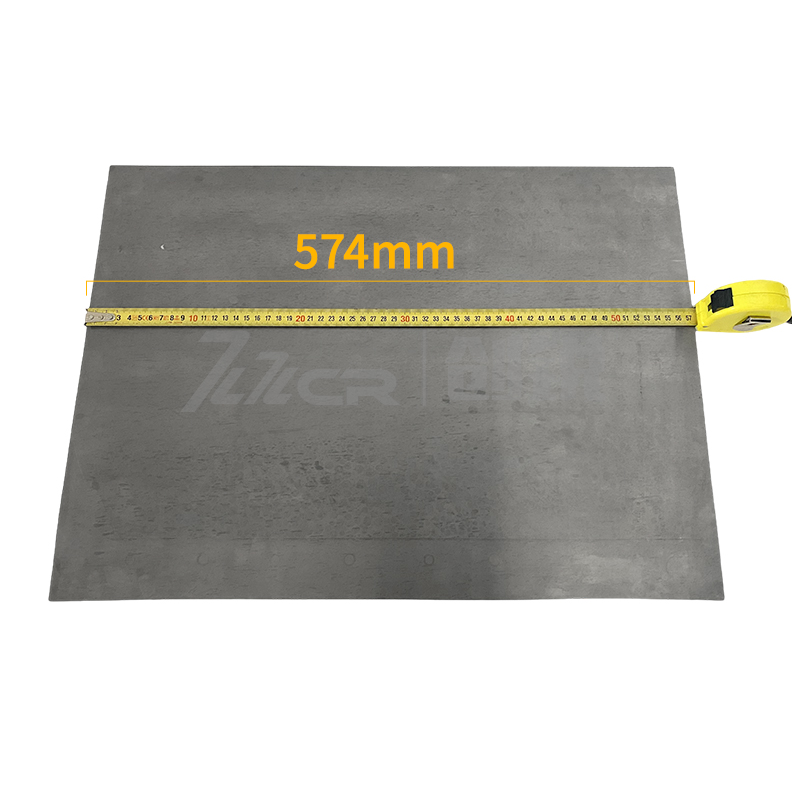

Tungsten carbide product is a kind of tungsten carbide as the main raw material, using powder metallurgy method through ball grinding, mixing, drying, pressing, sintering, heat preservation, cooling and a series of processes made of high hardness and high bending strength, high density, impact resistance, corrosion resistance and no rust alloy materials, according to the application requirements are usually made into plates, sheets, discs, round bars, strips or molded into different special-shaped cemented carbide.

There are many reasons that affect the deformation and bending of cemented carbide products, and it is necessary to analyze the specific situation of cemented carbide products, which may be caused by one factor or a combination of factors. The main reasons are: carbon gradient, cobalt gradient, temperature gradient, density gradient of pressed products, improper boat loading, shrinkage coefficient, etc.

In the lathe machining, it is usually used centripetal force to use the three-jaw or four-jaw chuck of the lathe to clamp the parts, and then process. In this way, it is easy to cause changes in machining accuracy under the action of force.

It is easy to deform after heat treatment.

For thin sheet mechanical parts, due to their very large length and diameter, they are more likely to bend after heat treatment. There may be a bulging phenomenon in the middle, the plane deviation increases, and on the other hand, due to the influence of various external factors, the parts are bent.

There is also the elastic deformation caused by external force

When performing tungsten carbide machining, there are several main reasons for the elastic deformation of parts. First, if the internal structure of some parts contains thin sheets, there will be higher requirements for the operation method, otherwise when the operator is positioning and clamping the parts, it cannot correspond with the design of the drawing, which is easy to lead to the generation of elastic deformation. The second is the unevenness of the lathe and fixture, so that the force on both sides of the part is uneven, resulting in the side with little force during cutting, and the part will be deformed under the action of force. Third, the positioning of the parts in the processing process is unreasonable, so that the rigidity and strength of the parts are reduced. Fourth, the existence of cutting force is also one of the reasons for the elastic deformation of parts.

These are all factors that cause bending and deformation of cemented carbide products. We must pay more attention in the processing process, once the deformation occurs, then the workpiece can only be scrapped, not to mention the waste of cost, the key is to re-replenish, delaying the customer's delivery.

Post time: May-08-2024