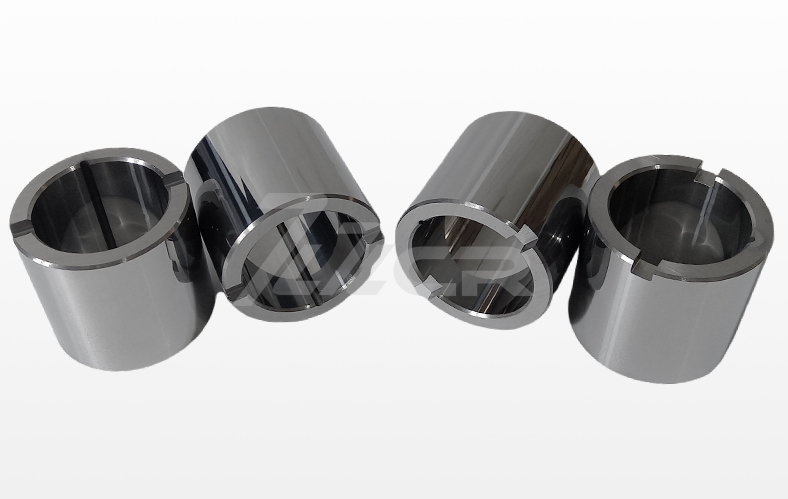

Tungsten carbide wear sleeve, as an advanced material integrating high hardness, high strength, high wear resistance and corrosion resistance, has shown good application potential in many industrial fields, and its application prospects are particularly broad.

First of all, as the global energy demand continues to grow, the extraction of oil, natural gas and other resources is becoming more and more frequent. In this context, tungsten carbide wear sleeves have been widely used in key equipment such as oil drilling tools and transportation pipelines due to their excellent wear resistance and corrosion resistance. In the future, with the continuous progress of exploration technology and the increase in mining difficulty, the performance requirements for wear-resistant sleeves will be further improved, which will provide a broader market space for cemented carbide wear-resistant sleeves.

Secondly, tungsten carbide wear sleeves also have great application potential in heavy industry, mining and other fields. In these areas, equipment often needs to operate in high-load, high-wear environments, and tungsten carbide wear sleeves are the ideal material to solve this problem. By optimizing the design and manufacturing process, tungsten carbide wear sleeves can further improve their wear resistance and service life, reducing maintenance costs and production risks for enterprises.

Post time: Sep-21-2024