The Cemented Carbide Nozzles For PDC Drill Bits And Cone Roller Bits In Oil Drilling

Description

PDC drill bits and cone roller bits are commonly used in oil drilling and geological drilling industry and the water holes on them are cemented carbide nozzles. The cemented carbide nozzles will be mainly applied to PDC drill bits and cone roller bits for flushing, cooling and lubricating drill bit tips, assisting rock breakage, and cleaning stone chips in the well bottom with drilling liquid in the working conditions of high pressure, vibration, sand and slurry impacting.

Types Of The Carbide Nozzles

There are two main types of the carbide nozzles for the drill bits. One is with thread, and the other is without thread. Carbide nozzles without thread are mainly used on the roller bit, carbide nozzles with thread are applied mostly on the PDC drill bit. According to different handling tool wrench, there are 6 types threaded nozzles for PDC bits:

1. Cross groove thread nozzles

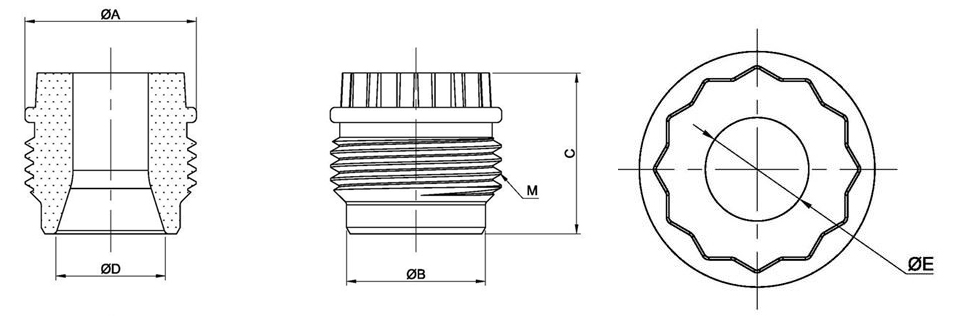

2. Plum blossom type thread nozzles

3. Outer hexagonal thread nozzles

4. Internal hexagonal thread nozzles

5. Y type (3 slot/grooves) thread nozzles

6. gear wheel drill bit nozzles and press fracturing nozzles

We can not only produce standard tungsten carbide nozzle, we also be able to produce the customized nozzles according to the drawings or samples.

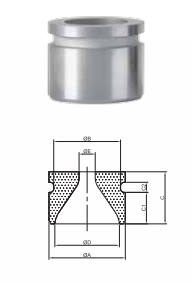

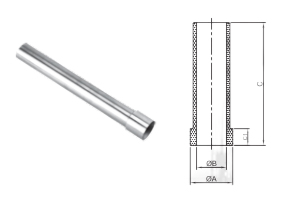

Cemented Carbide Nozzle For Cone Roller Bits:

The tungsten carbide nozzles is one of the important components for Cone Roller bits, Cemented carbide drill bit nozzle apply to flush, cool and lubricate the tips of the drill bit cutters , At the same time, the high-pressure fluid jetted out of the nozzles will help destroy the rock. Carbide nozzles also have hydraulic rock fragmentation effect. it can produce a balanced pressure distribution in the rock surface.As an advanced supplier of nozzles for roller cone drill bits, we offer a variety of types and size combinations for most downhole drilling applications. Conventional nozzle is cylindrical.Grades are designed for excellent corrosion & erosion resistance.Custom-molded nozzles could be provided upon drawings and grade requirements from customers.

| Stock No | ØA | ØB | C | C1 | C2 | ØD | ØE |

| ZZCR002301 | 18.9 | 16.3 | 18.8 | 11.9 | 4.0 | 14.7 | 6.4 |

| ZZCR002302 | 22.1 | 18.8 | 18.8 | 11.9 | 4.0 | 17.5 | 5.5 |

| ZZCR002303 | 30.0 | 26.3 | 20.6 | 12.4 | 4.0 | 25.4 | 7.1 |

| ZZCR002304 | 33.2 | 29.9 | 27.0 | 19.1 | 4.0 | 28.6 | 7.9 |

| ZZCR002305 | 37.8 | 34.2 | 28.6 | 20.5 | 4.0 | 33.3 | 25.4 |

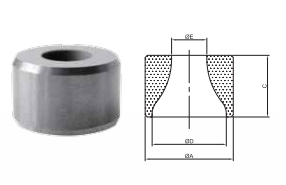

| Stock No | ØA | ØB | ØB1 | C | C1 | C2 | ØD | ØE |

| ZZCR002306 | 30.0 | 22.9 | 26.3 | 46.0 | 12.4 | 4.0 | 25.4 | 7.1 |

| ZZCR00230601 | 30.0 | 22.9 | 26.3 | 46.0 | 12.4 | 4.0 | 25.4 | 11.1 |

| ZZCR002307 | 33.2 | 21.6 | 29.9 | 61.9 | 19.1 | 4.0 | 28.6 | 7.1 |

| ZZCR00230701 | 33.2 | 21.6 | 29.9 | 61.9 | 19.1 | 4.0 | 28.6 | 10.3 |

| ZZCR002308 | 37.8 | 26.2 | 34.2 | 66.7 | 20.5 | 4.0 | 33.3 | 15.9 |

| ZZCR00230801 | 37.8 | 26.2 | 34.2 | 66.7 | 20.5 | 4.0 | 33.3 | 8.0 |

| ZZCR00230802 | 37.8 | 26.2 | 34.2 | 66.7 | 20.5 | 4.0 | 33.3 | 11.9 |

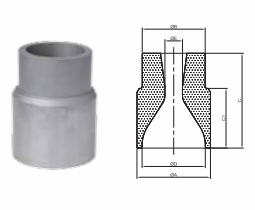

| Stock No | ØA | C | ØD | ØE |

| ZZCR002309 | 31.8 | 22.2 | 26.7 | 9.5 |

| ZZCR002310 | 20.3 | 12.6 | 15.2 | 14.3 |

| ZZCR002311 | 20.4 | 12.7 | 15.9 | 9.3 |

| Stock No | ØA | ØB | C | C1 | ØD | ØE |

| ZZCR002312 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 7.9 |

| ZZCR002313 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 9.5 |

| ZZCR002314 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 11.4 |

| ZZCR002315 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 14.5 |

| ZZCR002316 | 33.20 | 28.45 | 42.85 | 26.98 | 28.58 | 17.5 |

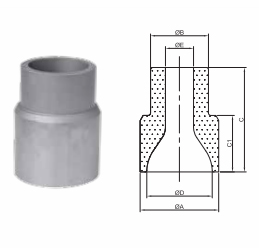

| Stock No | ØA | ØB | C | C1 | ØD | ØE |

| ZZCR002317 | 26.8 | 19.7 | 35.7 | 19.1 | 22.2 | 6.4 |

| ZZCR002318 | 33.2 | 28.4 | 42.9 | 27 | 28.6 | 7.9 |

| ZZCR002319 | 33.2 | 28.4 | 42.9 | 27 | 28.6 | 10.3 |

| ZZCR002320 | 33.2 | 28.4 | 42.9 | 27 | 28.6 | 14.3 |

| ZZCR002321 | 33.2 | 28.4 | 42.9 | 27 | 28.6 | 19.1 |

Cemented Carbide Nozzles For PDC Drill Bits:

The cemented carbide nozzles are mainly used for PDC drill bits for flushing, cooling and lubricating drill bit cutters. Meanwhile, the high pressure fluid jetted out of the nozzles will help break down the rock.

As a fully-integrated supplier, we provide the thread nozzles for PDC Drill Bits in a wide range of styles and sizes combinations for most down-hole drilling applications. Grades of thread nozzles for PDC are designed for excellent corrosion & erosion resistance. The nozzles could be made upon drawings and grade requirements from customers.

Thread nozzle of plum tooth wrench series:

| Stock No | ØA | ØB | C | ØD | ØE | M |

| ZZCR002322 | 27.1 | 21.9 | 25.4 | 17.5 | 5.6 | 1-1/16-12UN-2A |

| ZZCR002323 | 27.1 | 21.9 | 25.4 | 17.5 | 7.1 | 1-1/16-12UN-2A |

| ZZCR002324 | 27.1 | 21.9 | 25.4 | 17.5 | 8.7 | 1-1/16-12UN-2A |

| ZZCR002325 | 27.1 | 21.9 | 25.4 | 17.5 | 11.9 | 1-1/16-12UN-2A |

| ZZCR002326 | 27.1 | 21.9 | 25.4 | 17.5 | 15.9 | 1-1/16-12UN-2A |

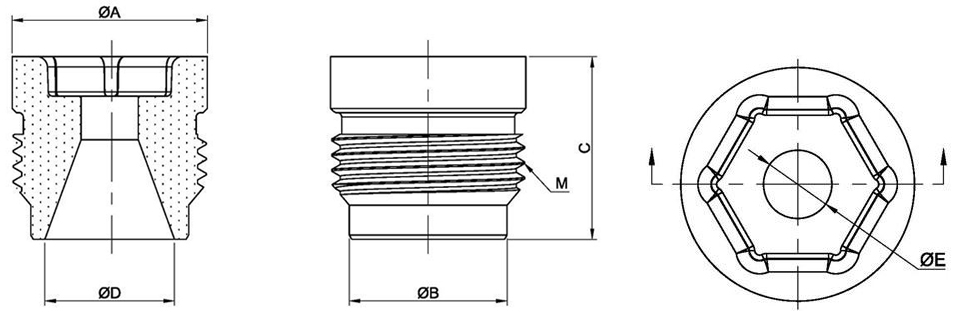

Thread nozzle of inner hexagon wrench series :

| Stock No | ØA | ØB | C | ØD | ØE | M |

| ZZCR002327 | 27.1 | 21.9 | 25.4 | 18 | 6.4 | 1’’-1/16-12UN-2A |

| ZZCR002328 | 27.1 | 21.9 | 25.4 | 18 | 7.9 | 1’’-1/16-12UN-2A |

| ZZCR002329 | 27.1 | 21.9 | 25.4 | 18 | 12.7 | 1’’-1/16-12UN-2A |

| ZZCR002330 | 27.1 | 21.9 | 25.4 | 18 | 15.9 | 1’’-1/16-12UN-2A |

| ZZCR002331 | 19.1 | 16.1 | 23 | 13 | 6.4 | 3/4’’-12UN-2A |

| ZZCR002332 | 19.1 | 16.1 | 23 | 13 | 7.1 | 3/4’’-12UN-2A |

| ZZCR002333 | 19.1 | 16.1 | 23 | 13 | 7.9 | 3/4’’-12UN-2A |

| ZZCR002334 | 19.1 | 16.1 | 23 | 13 | 9.5 | 3/4’’-12UN-2A |

| ZZCR002335 | 19.1 | 16.1 | 23 | 13 | 11.1 | 3/4’’-12UN-2A |

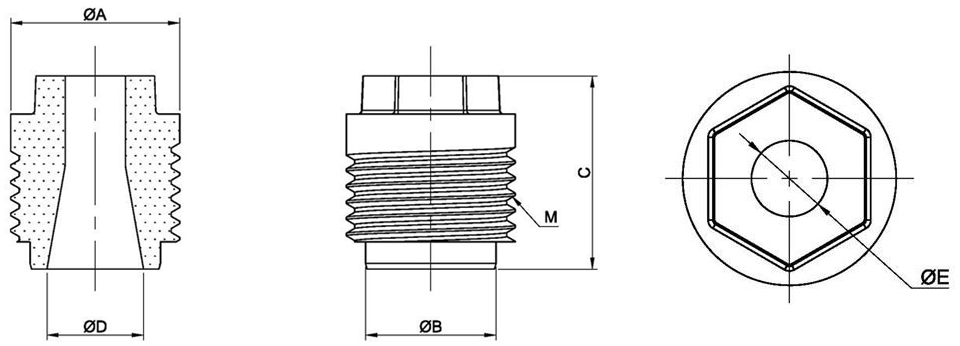

Thread nozzle of external hexagon wrench series :

| Stock No | ØA | C | ØE | M |

| ZZCR002336 | 25.4 | 28.6 | 7.1 | 1"-14UNS-2A |

| ZZCR002337 | 25.4 | 28.6 | 15.9 | 1"-14UNS-2A |

| ZZCR002338 | 25.4 | 28.6 | 18.6 | 1"-14UNS-2A |

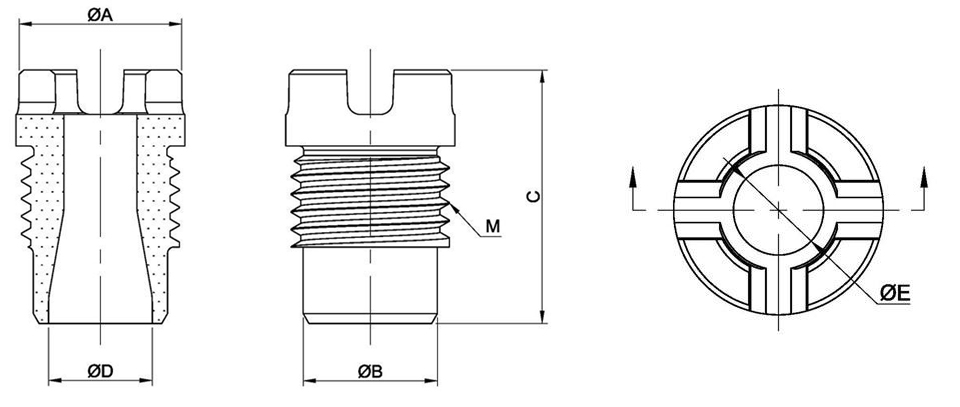

Thread nozzle of castle top wrench series :

| Stock No | ØA | ØB | C | ØD | ØE | M |

| ZZCR002339 | 20.3 | 16.1 | 30.5 | 12.5 | 5.6 | 3/4’’-12UN-2A |

| ZZCR002340 | 20.3 | 16.1 | 30.5 | 12.5 | 6.4 | 3/4’’-12UN-2A |

| ZZCR002341 | 20.3 | 16.1 | 30.5 | 12.5 | 7.1 | 3/4’’-12UN-2A |

| ZZCR002342 | 20.3 | 16.1 | 30.5 | 12.5 | 9.5 | 3/4’’-12UN-2A |

| ZZCR002343 | 20.3 | 16.1 | 30.5 | 12.5 | 10.3 | 3/4’’-12UN-2A |

| ZZCR002344 | 20.3 | 16.1 | 30.5 | 12.5 | 11.1 | 3/4’’-12UN-2A |

| ZZCR002345 | 20.3 | 16.1 | 30.5 | 12.5 | 11.9 | 3/4’’-12UN-2A |

| ZZCR002346 | 20.3 | 16.1 | 30.5 | 12.5 | 12.7 | 3/4’’-12UN-2A |

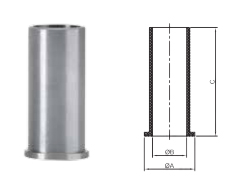

Water nozzle hole jacket:

| Stock No | ØA | ØB | C |

| ZZCR002347 | 28.5 | 22.0 | 40 |

| ZZCR002348 | 28.5 | 22.0 | 70 |

| ZZCR002349 | 24.6 | 18.0 | 50 |

| ZZCR002350 | 22.9 | 18.0 | 35 |

| ZZCR002351 | 16.5 | 11.5 | 40 |

| Stock No | ØA | ØB | C | C1 |

| ZZCR002352 | 17.0 | 11.1 | 76 | 9.5 |

| ZZCR002353 | 24.2 | 17.5 | 40 | 9.5 |

| ZZCR002354 | 24.2 | 17.5 | 50 | 9.5 |

| ZZCR002355 | 24.2 | 17.5 | 80 | 9.5 |

| ZZCR002356 | 24.2 | 17.5 | 95 | 9.5 |

Grade Offering

A collection of grades are specially for the needs of thread nozzles for PDC Drill Bits. Details of some grades are as follows:

| Grades | Physical Properties | Major Application And Characteristics | ||

| Hardness | Density | TRS | ||

| HRA | g/cm3 | N/mm2 | ||

| CR35 | 88.5-89.5 | 14.30-14.50 | ≥2800 | It is suitable to produce thread nozzles due to high hardness and good wear-resistance. |

| CR25 | 88.7-89.7 | 14.20-14.50 | ≥3200 | It is suitable to produce high pressure nozzle, threaded nozzles used in oil & gas and chemistry industry due to high impact-resistance and wear resistance. |

Our Advantages

● Complete series of nozzles for roller cone drill bits

● Excellent corrosion & erosion resistance

● 100% original raw material

● Quick delivery 3~5 weeks

● High precision size controlled

● Customized nozzle accepted

Our Service

● Material inspection and approval

● Dimension inspection and approval

● Sample grade analysis service available

● OEM and ODM accepted

● Detailed grade evaluation

● Metallurgical services

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope