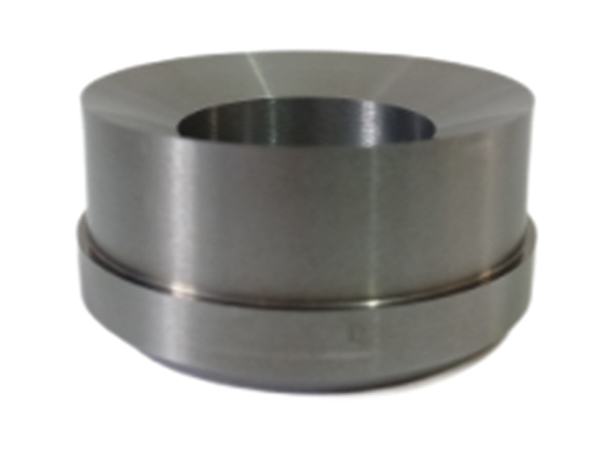

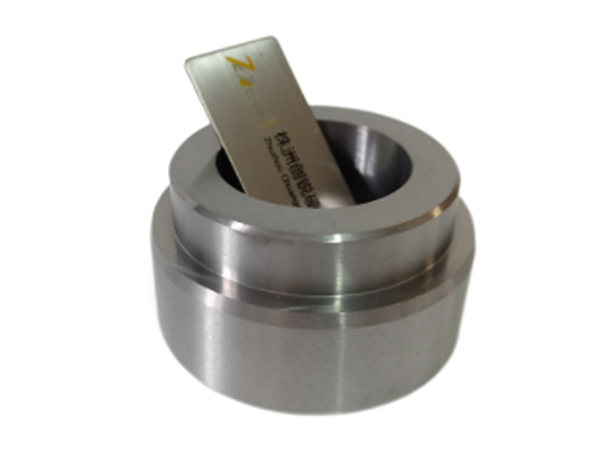

Tungsten Carbide Bottom Insert For MWD Pulser

Description

Tungste carbide orifice/sleeve are widely used in drilling fluid diversion, scour, sealing and pulse signal feedback and so on of MWD & LWD. Signal shaft poppet tips and carbide pulser parts for MWD platforms.Such as the poppet end,bottom sleeve, mushroom head (main valve core),350/650/1200 lift valve、flow seperator、nose cap、650/1200 upper bearing sleeve,lower bearing sleeve,spacer sleeve, seat, nozzle etc.

Tungsten Carbide bottom insert are engineered to provide superior wear, corrosion and impact resistance. Made from a combination of cobalt podwer and nickel powder , these orifice are ideal for a variety of applications in the oil and gas industry.

Our bottom sleeve uses a unique composition of 93.6% Cobalt,6.2%Nickel,Other metal 0.2%, with a density of 14.3g/cm3 and a hardness of HRA88-89. This high density and hardness make them extremely durable even in the harshest conditions.Our bottom inserts are available in a variety of sizes, ranging from ID 1.60 inches to 1.28 inches, Whether you need bottom for MWD and LWD parts, pulse generators or Muleshoe assemblies.our carbide Bottom sleeve are the perfect solution.

Specifications

| Part NO. | OD Size | ID Size | Height Size |

| 422568 | Ø2.44'' | Ø1.20'' | Ø1.18'' |

| 422569 | Ø2.44'' | Ø1.23'' | Ø1.18'' |

| 422570 | Ø2.44'' | Ø1.25'' | Ø1.18'' |

| 422571 | Ø2.44'' | Ø1.28'' | Ø1.18'' |

| 422572 | Ø2.44'' | Ø1.35'' | Ø1.18'' |

| 422573 | Ø2.44'' | Ø1.40'' | Ø1.18'' |

| 422574 | Ø2.44'' | Ø1.50'' | Ø1.18'' |

| 422575 | Ø2.44'' | Ø1.55'' | Ø1.18'' |

| 422576 | Ø2.44'' | Ø1.60'' | Ø1.18'' |

Fully stocked in sizes from 1.28" to 1.60" ready.

The size can be customized according to customer’s requirements.

| Part NO. | OD size | ID size | Height size |

| 406027 | Ø2.435’’ | Ø1.60’’ | 3.198’’ |

| 406028 | Ø2.435’’ | Ø1.50’’ | 3.198’’ |

| 406029 | Ø2.435’’ | Ø1.40’’ | 3.198’’ |

| 406030 | Ø2.435’’ | Ø1.35’’ | 3.198’’ |

| 406032 | Ø2.435’’ | Ø1.28’’ | 3.198’’ |

Product Feature of tungsten carbide Bottom insert:

1. Excellent abrasion resistance

2. Good corrosion resistance

3. High fractural strength

4. Long service life

Production characteristics of the company:

About Chuangrui Carbide, we have focused on the cemented carbide industry for many years. We not only have a complete set of processing equipment, but also unique processing technology. This enables us to produce and process special-shaped non-standard parts with precision and quickly.We understand the importance of quality in the oil and gas industry. That's why we're committed to designing top-quality products that meet the highest industry standards. Our tungsten carbide bottom inserts are no exception.

Choose Chuangrui Carbide for all your carbide needs and experience the highest quality and reliability. Our team of experts are ready to assist you and provide customized solutions to meet your specific requirements. Trust our expertise and make us your preferred partner in the carbide industry.

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope