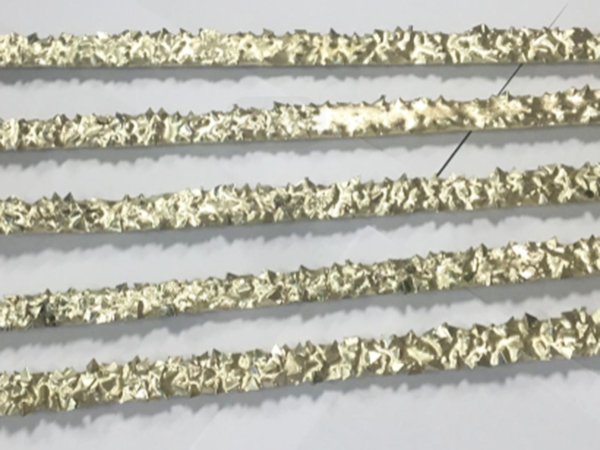

Tungsten Carbide Composite Rods Or YD Welding Rods For Drilling Tools

Description

Tungsten carbide composite rods/YD welding rods is mainly used to overlay the worn-out and cutting usage workpieces in oil,mining,coal mining,geology,construction and other industries.Such as :Reamers,Openers,Fishing tools,Casing cutters,Milling tools,Coring tools,Stabilizers,Screw feeders,slurry Paddles,Construction drilling,Foundry sand mixing,General abrasive wear prevention etc.

Our cemented carbide composite rods adopts scrap top hammer to break the particles,which does not contain impurities,and the cutting and wear resistance is much better than that of the mixed broken particles,guarantee product performance stability.

The exclusive screening process of broken particles ensures that the required broken particles are multi-angle,not flat.High-quality solder,mature casting process,more uniform broken particles of composite rods,better flow performance,and improve customer production efficiency.

Scrap Top Hammer

Break The Particles

Carbide Composite Rod

Milling Shoes

Two grades are available, either BBW for wear applications or BBC for cutting applications.Sizes stocked as below:

| Grain size | 1.6-3.2MM | 1/16"- 1/8"BBW |

| 3.2-4.8MM | 1/8"- 3/16"BBW | |

| 4.8-6.4MM | 3/16"- 1/4"BBC | |

| 6.4-8.0MM | 1/4"- 5/16"BBC | |

| 8.0-9.5MM | 5/16"- 3/8"BBC | |

| 9.5-12.7MM | 3/8"-1/2"BBC |

Other sizes on request.Standard Tungsten Carbide Grit content = 65% Also available 50%, 60% & 70%, Balance: Matrix(CuZnSn)

Specially selected Tungsten Carbide Grit either "blocky" with sharp edges for cutting application or "rounded" Tungsten Carbide Grit for wear applications are produced under stringent quality controls. Material is thoroughly cleaned to ensure the best possible wetting properties, both during manufacture and application. Stringent quality control procedures ensure repeatability of excellent quality, low fuming rod. The Tungsten Carbide Grit is blended with a Copper, Nickel and Zinc alloy, to produce a premium quality Composite Rod.(Matrix designation AWS-RBCuZn-D).

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope