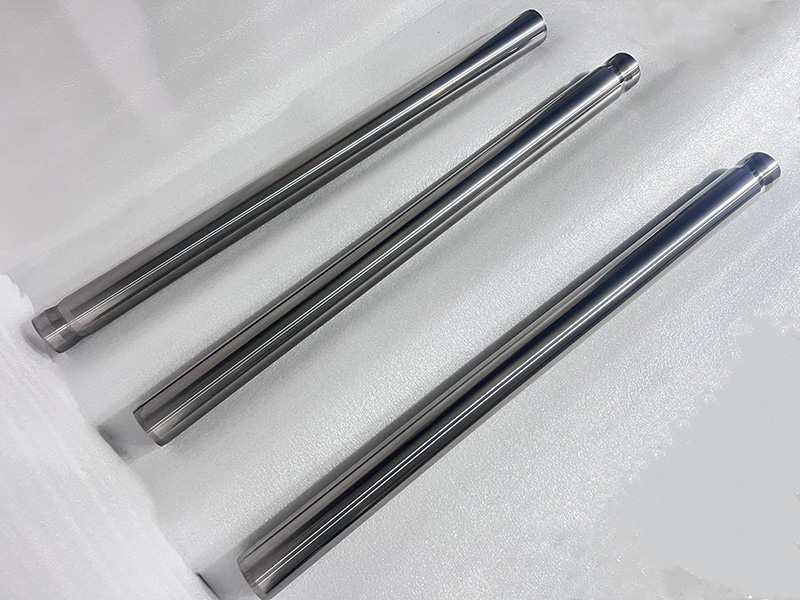

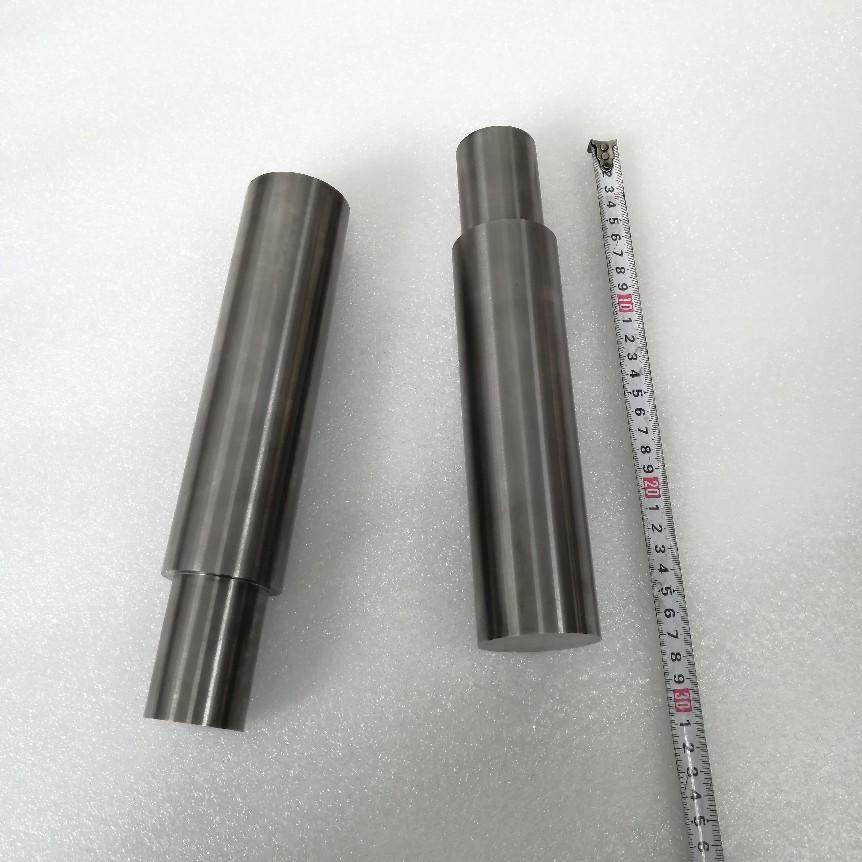

Tungsten Carbide Compressor Plunger Used In Oil And Gas Industry

Description

Cemented Carbide Plunger are used in hyper compressors to compress ethylene gas to the reactor pressure. This requires a wear resistant plunger material that combines the necessary mechanical properties and wear resistance for these extreme conditions. The only material that has these properties is cemented carbide.

Photos

Tungsten carbide Plungers

Large size carbide plunger rod

Carbide plungers

Solid tungsten carbide plungers

No-magnet tungsten carbide plunger

carbide pistons

Advantage

1. Over 15 years manufacturing experience with advanced equipment and technology.

2. Guarantee product performance, save more time and work efficiency.

3. The most suitable Carbide grade can be customized for each application.

4. Keep high and consistent quality.

Features

1. Extreme Hardness and Wear Resistance:

- Tungsten carbide is one of the hardest materials available, making it ideal for high-pressure applications where wear is a major concern.

- It maintains its shape and surface finish even after prolonged use.

2. High Compressive Strength:

- Tungsten carbide can withstand the extreme pressures generated in hyper compressors without deforming or failing.

3. Corrosion Resistance:

- Suitable for handling corrosive gases and chemicals commonly processed in hyper compressors.

4. Thermal Stability:

- Carbide plungers can operate efficiently at high temperatures, which are often generated during high-pressure compression.

5. Long Service Life:

- Reduces downtime and maintenance costs, as carbide plungers last significantly longer than traditional materials like steel.

Application

Industries Using Hyper Compressors with Carbide Plungers

- Petrochemical Industry: For LDPE and HDPE production.

- Chemical Manufacturing: For high-pressure synthesis of chemicals.

- Energy Sector: For hydrogen compression and storage.

- Research and Development: For material testing and high-pressure experiments.

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope