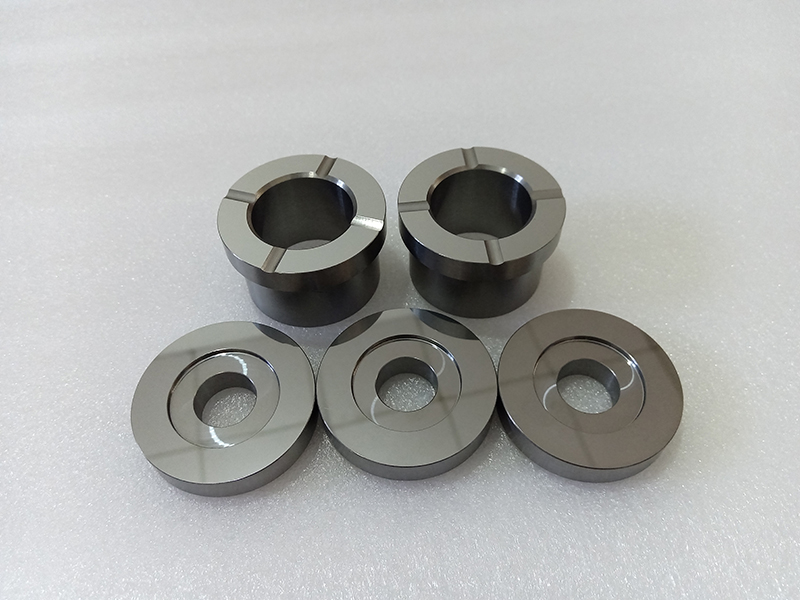

Tungsten carbide dynamic and static rings for sand mill or bead mill parts

Description

Tungsten carbide dynamic and static rings play an important role in the market of mechanical seal industry, tungsten carbide dynamic and static rings have the characteristics of wear resistance, corrosion resistance, no deformation and high pressure resistance, they are widely used in petrochemical industry and other industries which require super sealing performance. Due to the excellent properties of tungsten carbide materials, tungsten carbide dynamic and static rings are also used as the mechanical seal surface of pumps and compressors. Tungsten carbide dynamic and static rings can also be used to seal the gap between the rotating shaft and the housing fixed in the pump and mixer equipment, so that liquid cannot leak out through this gap. Tungsten carbide dynamic and static rings have many applications in petrochemical and other sealing industries due to their high hardness and good anti-corrosion performance.

Specifications

Common size as below:(OEM accepted)

| (OD:mm) | (ID:mm) | (T:mm) |

| 38 | 20 | 6 |

| 45 | 32 | 13 |

| 72 | 52 | 5 |

| 85 | 60 | 5 |

| 120 | 100 | 8 |

| 150 | 125 | 10 |

| 187 | 160 | 18 |

| 215 | 188 | 12 |

| 234 | 186 | 10 |

| 285 | 268 | 16 |

| 312 | 286 | 12 |

| 360 | 280 | 12 |

| 470 | 430 | 15 |

Photos

Our Advantages

1. Famous brand raw materials.

2. Multiple detection (powder, blank, finished QC to assure the material and quality).

3. Mold design ( we can design and produce the mold according to customers’ request ).

4. Press difference ( mold press, preheat, cold isostatic press to assure the uniform density ).

5. 24 hours online, Delivery fast.

More questions, welcome to send us inquiry!

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope