Tungsten Carbide Industrial Knives

Description

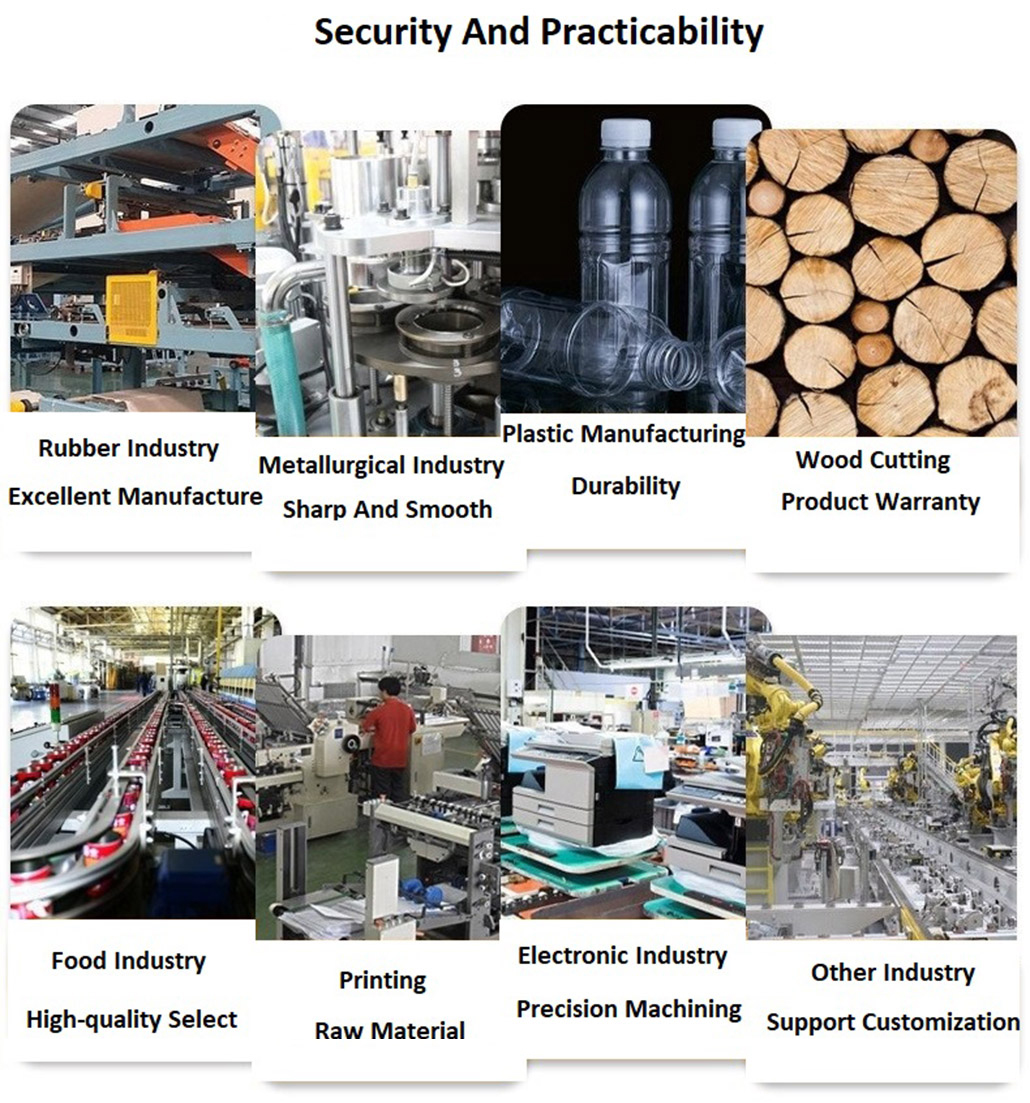

Tungsten carbide industrial knives and blades with hardness and wear resistance,customized size and grade are acceptable. Which have been applied in many industries, such as packaging, Li-ion battery, metal processing, recycling, medical treatment and so on.

Features

• Original tungsten carbide materials

• Precision machining & Quality guarantee

• Keep the blade sharp for long-lasting durability

• Professional factory services and cost-effective products

• Varied sizes and grades for each application

GRADE OF TUNGSTEN CARBIDE KNIVES AND BLADE

| Grade | Grain Size | Co% | Hardness (HRA) | Density (g/cm3) | T.R.S (N/mm2) | Application |

| UCR06 | Ultrafine | 6 | 93.5 | 14.7 | 2400 | Ultrafine alloy grade with High hardness and wear resistance.Suitable for kinds of wear parts making,or high precision industrial cutting tools under low impact conditions. |

| UCR12 | 12 | 92.7 | 14.1 | 3800 | ||

| SCR06 | Submicron | 6 | 92.9 | 14.9 | 2400 | Submicron alloy grade with High hardness and wear resistance.Suitable for kinds of wear parts making,or high wear resistance industrial cutting tools under low impact conditions. |

| SCR08 | 8 | 92.5 | 14.7 | 2600 | ||

| SCR10 | 10 | 91.7 | 14.4 | 3200 | Submicron alloy grade with High hardness and High toughness, Suitable for different field Industrial slitting applications.Such as Paper, cloth,films,non ferrous metals etc.. | |

| SCR15 | 15 | 90.1 | 13.9 | 3200 | ||

| MCR06 | Medium | 6 | 91 | 14.9 | 2400 | Medium alloy grade with High hardness and wear resistance.Suitable for industrial cutting and crushing tools under low impact conditions. |

| MCR08 | 8 | 90 | 14.6 | 2000 | ||

| MCR09 | 9 | 89.8 | 14.5 | 2800 | ||

| MCR15 | 15 | 87.5 | 14.1 | 3000 | Medium alloy grade with High toughness.Suitable for industrial cutting and crushing tools under high impact conditions. It has good toughness and impact resistance. |

Other Product You May Like

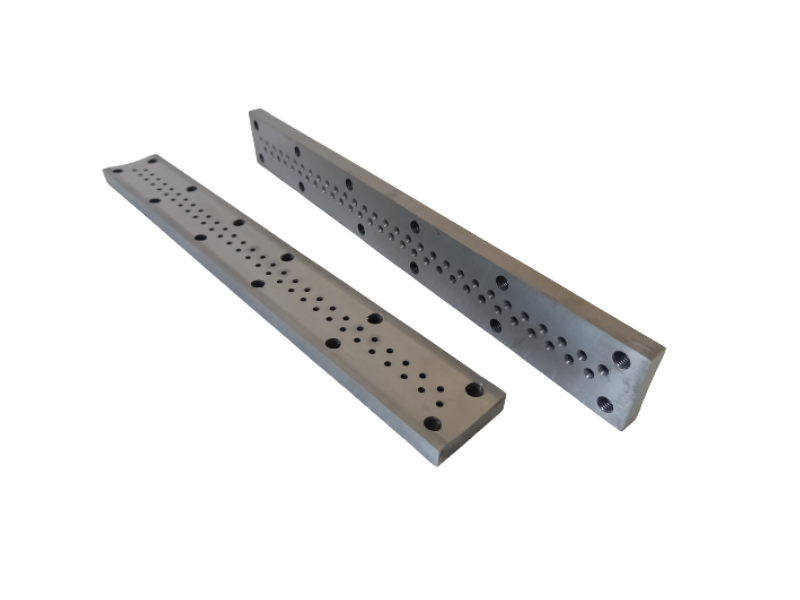

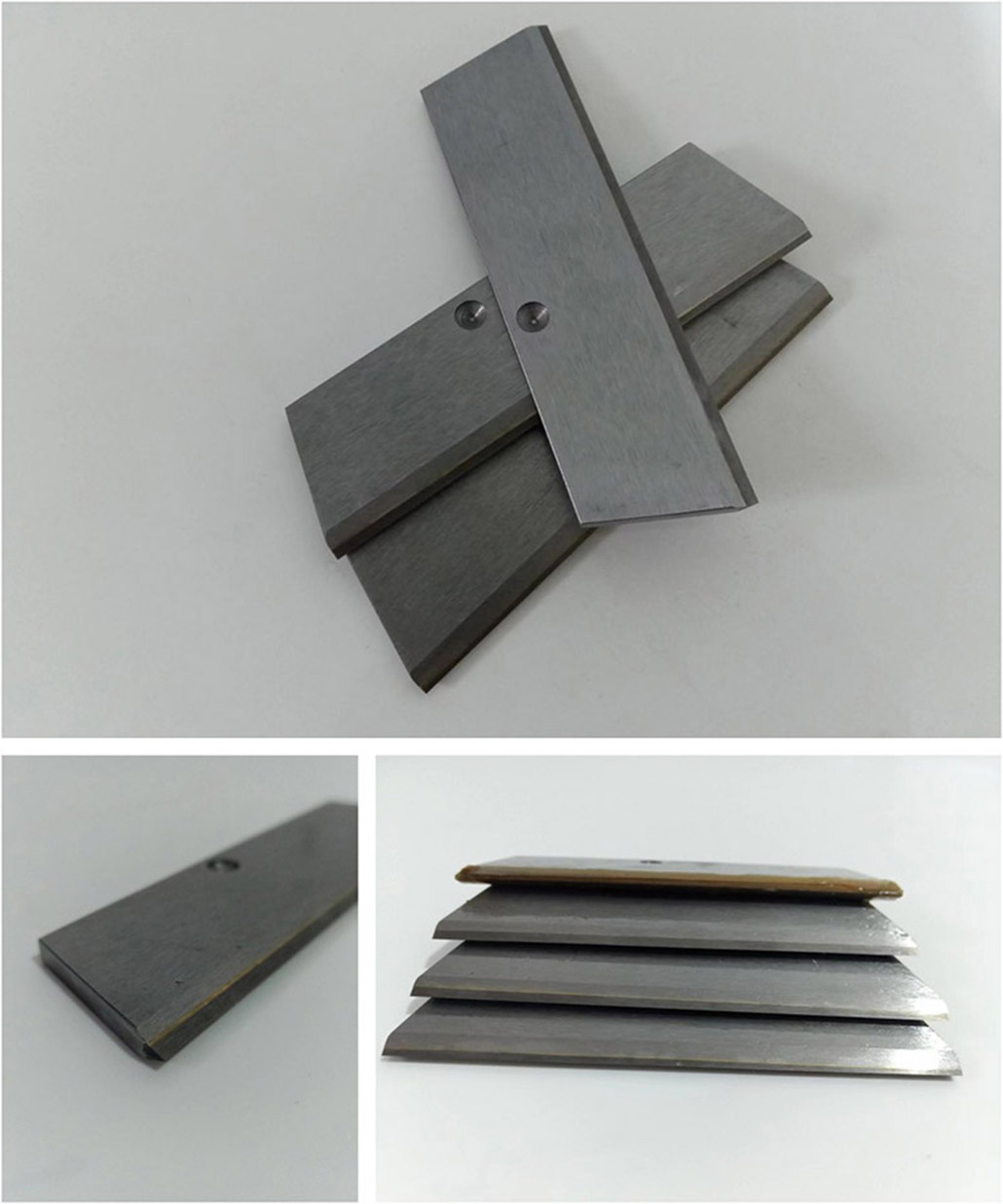

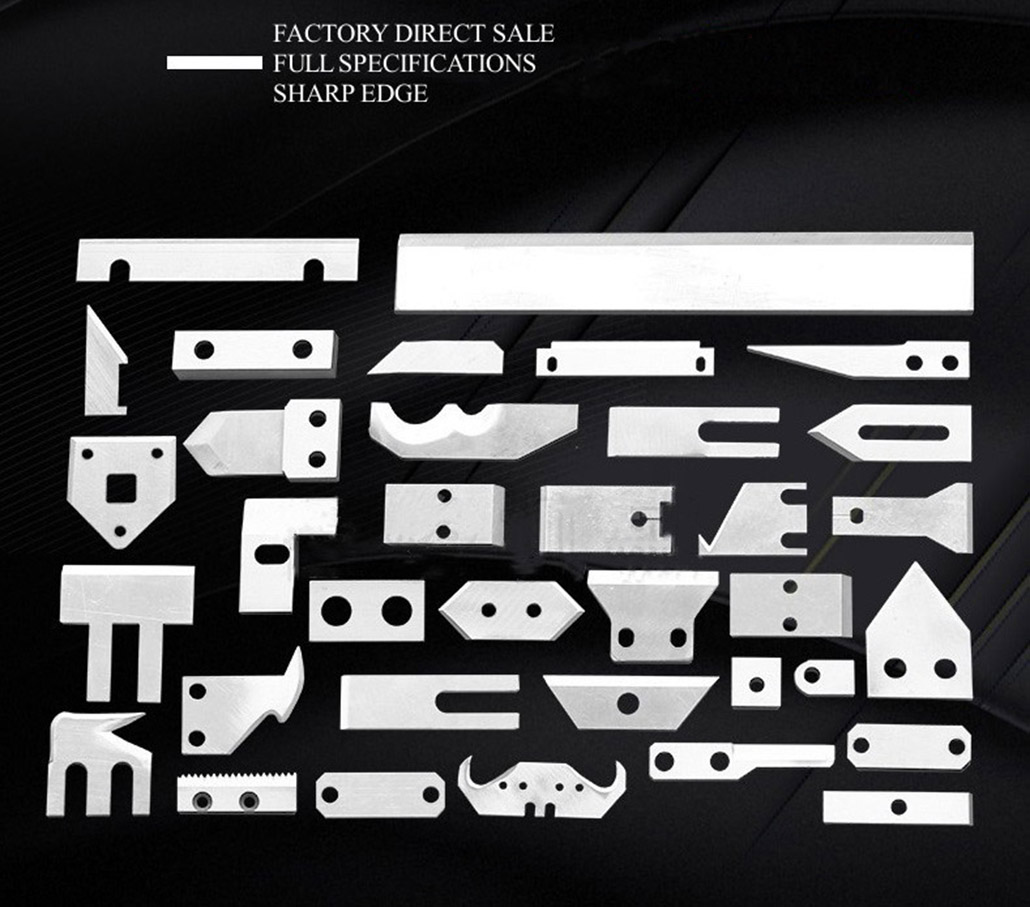

Customized Carbide Special Blade

Carbide Plastic And Rubber Knives

Carbide Plastic Film Cutting Knife

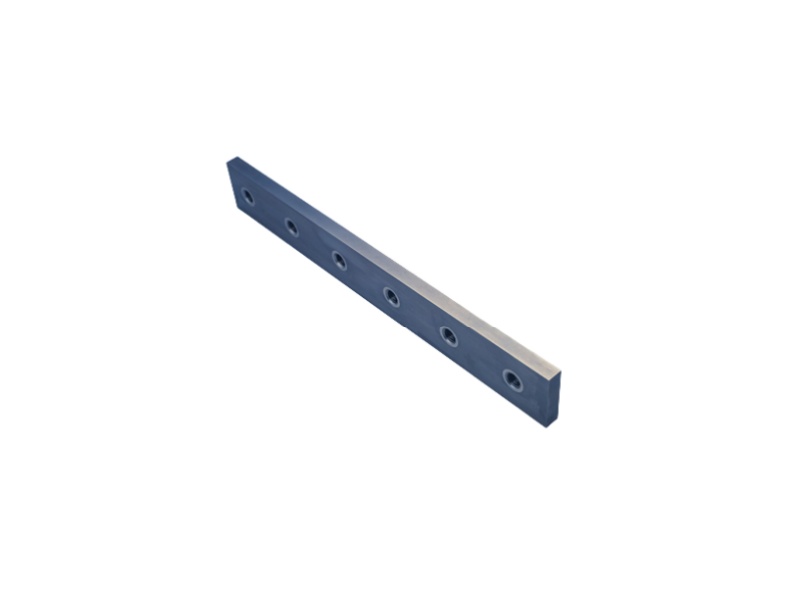

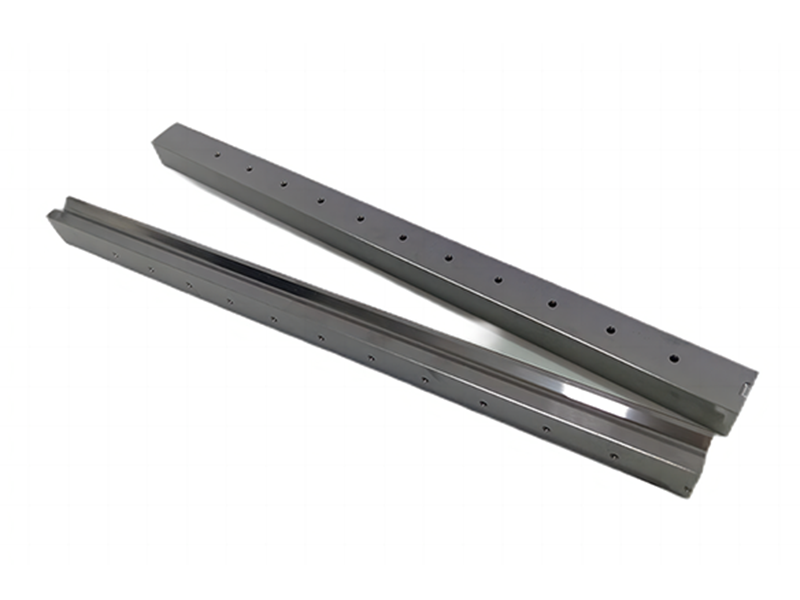

Carbide Shearing Slitting Knife

Cemented Carbide Square Knives

Carbide Strip Blade With Hole

Adantage

• Over 15 years manufacturing experience with advanced equipment and technology.

• High corrosion & heat resistance; Excellent cutting effect long service life.

• High precision, Fast cutting, Durability and Stable performance.

• Mirror polishing surface; Exceed standard smooth cutting less downtime.

Applications

Tungsten carbide knives and blades for cutting and perforation in packing, cutting, and perforating machines and many other machines used in the food, pharmaceutical, bookbinding, typographic, paper, tobacco, textile, wood, furniture, and metal industries, among many others.

OUR QUALITY CONTROL

Quality Policy

Quality is the soul of products.

Strictly process control.

Zero tolerate of defects!

Passed ISO9001-2015 Certification

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope