Tungsten Carbide Plate for Mold

Description

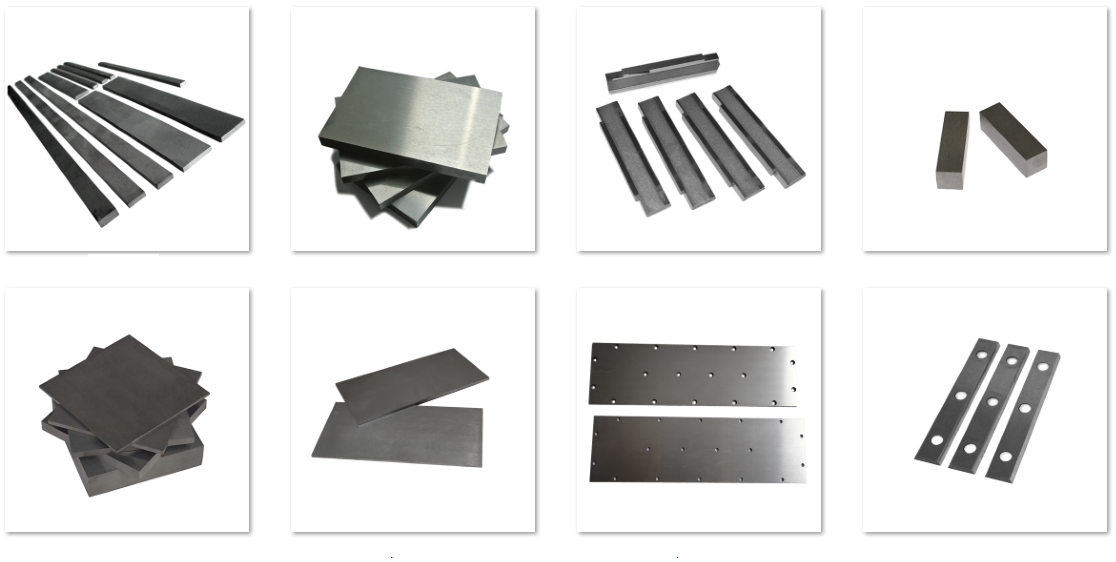

Tungsten carbide plate which has good durability and strong impact resistance, can be used in hardware and standard stamping dies.

Tungsten carbide plate is widely used in electronics industry, motor rotor, stator, LED lead frame, EI silicon steel sheet and other all tungsten carbide blocks must be inspected strictly and only those without any damage, such as porosity, bubbles, cracks, etc. can be shipped out.

Why Choose Tungsten Carbide Material?

Cemented carbide has a series of excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance, especially its high hardness and wear resistance, even at a temperature of 500 °C, it remains basically unchanged, and it still has a high hardness at 1000 °C. Therefore, it is widely used in machinery. The physical properties of tungsten carbide are at least 3 times that of steel. It can be made into all kinds of carbide plates.

Photos For Reference

Common Size Information:(Oem Is Accepted)

| Thickness | Width | Length |

| 1.5-2.0 | 150 | 200 |

| 2.0-3.0 | 200 | 250 |

| 3.0-4.0 | 250 | 600 |

| 4.0-6.0 | 300 | 600 |

| 6.0-8.0 | 300 | 800 |

| 8.0-10.0 | 300 | 750 |

| 10.0-14.0 | 200 | 650 |

| >14.0 | 200 | 500 |

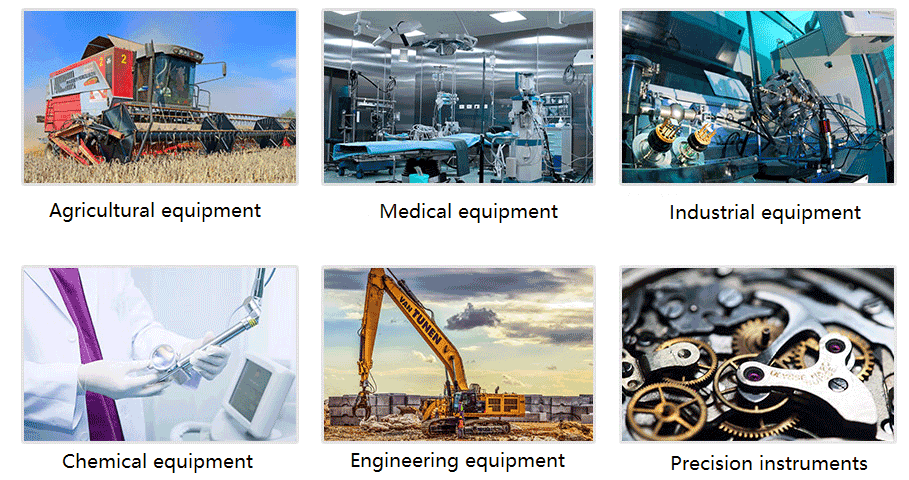

Applications

Chuangrui’s Cemented Carbide Plate Futures

1. Excellent thermal stability and high temperature deformation resistance.

2. High mechanical temperature at high temperatures.

3. Good thermal shock resistance.

4. High thermal conductivity.

5. Excellent oxidation control ability.

6. Corrosion resistance at high temperatures.

7. Excellent corrosion resistance against chemicals.

8. High abrasion resistance.

9. Long service life.

Welcome to contact us in anytime!

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope