tungsten carbide rotors, tungsten carbide grinding rotor

Description

Tungsten carbide rotor is the most important part in sand mill or bead mill.

With more than 15 years experience in the field of chemical industry, We have mature technology and team to suggest you design the most suitable size.

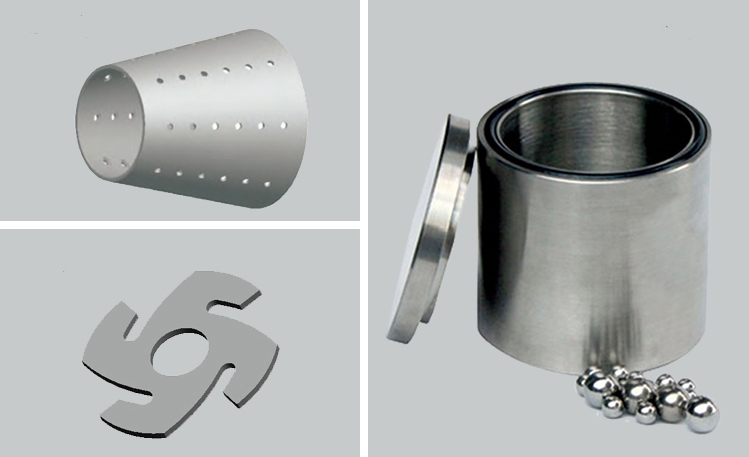

Usually, we produce three types of rotors as below:

1. Pin type grinding rotor, it is commonly used in sand mill machine.

2. Disc type grinding rotor.

3. Hammer type grinding rotor.

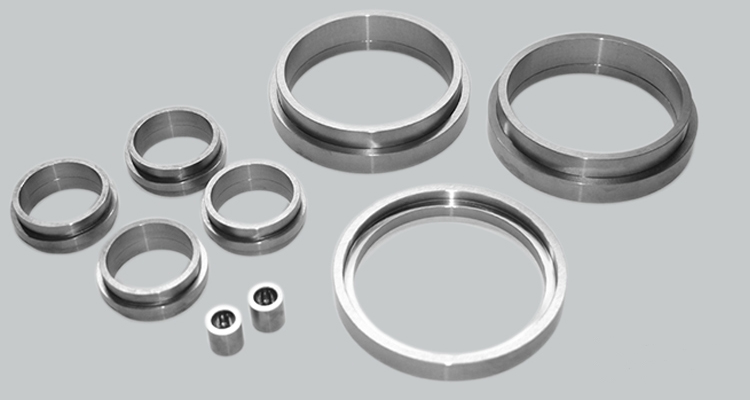

Related wear parts.

Our Advantages

1. Famous brand raw materials.

2. Multiple detection (powder, blank, finished QC to assure the material and quality).

3. Mold design ( we can design and produce the mold according to customers’ request ).

4. Press difference ( mold press, preheat, cold isostatic press to assure the uniform density ).

5. 24 hours online, Delivery fast.

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope