tungsten carbide spherical button

Description

Cemented carbide spherical teeth are widely used in snow plow equipment for oil drilling and snow removal. In addition, cemented carbide ball teeth are also well used in cutting tools and mining machinery, road maintenance and coal drilling tools. The cemented carbide ball teeth used in mines are mainly used as tools in quarrying, mining, tunneling and civil buildings.

Application

Cemented carbide button are widely used in oil field drilling and snow removal, snow plow or other equipment because of their unique properties. According to different drilling machines, such as cone bits, DTH bits, geological drilling tools, cemented carbide ball teeth are divided into different standard patterns: P-flat top position, Z-coin ball position, X-wedge position. Stability and high technology ensure the high quality of our products, carbide ball teeth are often used as shearer drilling tools, mining machinery tools and road maintenance tools to snow and road cleaning. Cemented carbide ball teeth are also widely used as excavation tools in quarrying, mining, tunnel excavation and civil buildings. In addition, it is also used as a bit fitting for heavy-duty rock drill or deep-hole drill tool fitting.

Features

Cemented carbide is the best material to produce cemented carbide ball teeth which are widely used in DTH hammer drilling industry.

Carbide button are widely used in mining, quarrying and cutting because of their high hardness. They can also be used in heavy excavator bits.

Grade

| Grade | Density g/cm3 | T.R.S Mpa | Hardness HRA | Application |

| CR4C | 15.10 | 1800 | 90.0 |

Mainly used for cutting hard and soft materials of impact drill. |

| CR6 | 14.95 | 1900 | 90.5 |

Used as electric coal bits, coal picks, petroleum cone bits and scraper ball-tooth bits. |

| CR8 | 14.80 | 2200 | 89.5 |

Used as core drills, electric coal drills, coal picks, petroleum cone drills and scraper ball-tooth drills. |

| CR8C | 14.80 | 2400 | 88.5 |

Mainly used as ball tooth of medium and small impact bit and as bearing bush of rotary exploration drill. |

| CR11C | 14.40 | 2700 | 86.5 |

Most are used in impact drills and in cone drills to cut the ball teeth of high-hardness materials. |

| CR13C | 14.2 | 2850 | 86.5 |

mainly used for cutting ball teeth of medium and high hardness materials in rotary impact drills. |

| CR15C | 14.0 | 3000 | 85.5 |

Used for oil cone bit and medium-soft and medium-hard rock cutting tools. |

Size

OEM are accepted.

Standard size of tungsten carbide button as below:

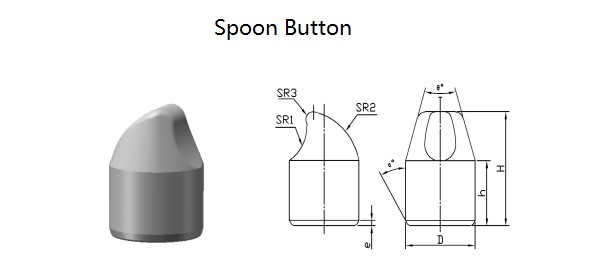

| Type | Dimension(mm) | ||||||||

| D | H | h | Ɵ° | SR1 | SR2 | SR3 | α° | e | |

| S1015 | 10.25 | 15 | 9.8 | 50 | 12 | 20 | 3 | 18 | 1.2 |

| S1116 | 11.3 | 16.5 | 10.2 | 50 | 15 | 24 | 3 | 18 | 1.2 |

| S1218 | 12.35 | 18 | 11 | 36 | 20 | 25 | 2.5 | 18 | 1.5 |

| S1319 | 13.35 | 19 | 12 | 50 | 15 | 20 | 3 | 18 | 1.5 |

| S1421 | 14.35 | 21 | 12.5 | 40 | 12 | 25 | 3 | 18 | 1.8 |

| S1521 | 15.35 | 21 | 12 | 50 | 20 | 30 | 3 | 18 | 1.8 |

| S1624 | 16.35 | 24 | 13 | 30 | 15 | 20 | 3 | 18 | 2 |

| S1827 | 18.25 | 27 | 14.5 | 30 | 18 | 20 | 3 | 18 | 2 |

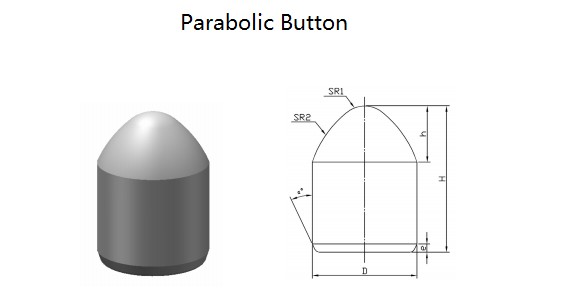

| Type | Dimension(mm) | |||||||

| D | H | SR1 | SR2 | h | α° | β° | e | |

| D0711 | 7.25 | 11 | 1.9 | 8.7 | 3.9 | 20 | 25 | 1.6 |

| D0812 | 8.25 | 12 | 2.5 | 9 | 4.5 | 20 | 25 | 1.6 |

| D0913 | 9.25 | 13 | 2.5 | 11 | 5 | 20 | 25 | 1.8 |

| D1015 | 10.25 | 15 | 3.2 | 11.8 | 5 | 20 | 25 | 1.8 |

| D1117 | 11.3 | 17 | 3 | 13.5 | 6 | 20 | 25 | 1.8 |

| D1218 | 12.35 | 18 | 3 | 12 | 6.5 | 20 | 20 | 2 |

| D1319 | 13.35 | 19 | 3.5 | 13.5 | 7.1 | 20 | 20 | 2 |

| D1420 | 14.35 | 20 | 4.2 | 13 | 8 | 20 | 20 | 2 |

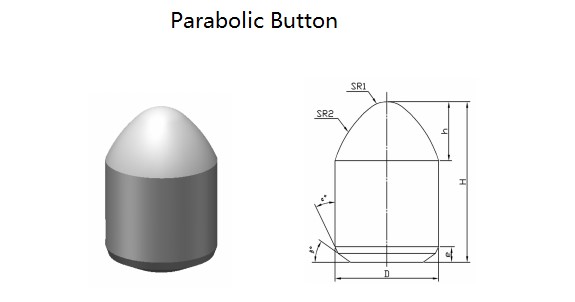

| Type | Dimension(mm) | ||||||

| D | H | SR1 | SR2 | h | α° | e | |

| D0711A | 7.25 | 11.0 | 1.9 | 8.7 | 3.9 | 18 | 1 |

| D0812A | 8.25 | 12.0 | 2.5 | 9 | 4.5 | 18 | 1 |

| D0913A | 9.25 | 13.0 | 2.5 | 11 | 5 | 18 | 1 |

| D1015A | 10.25 | 15.0 | 3.2 | 11.8 | 5 | 18 | 1.2 |

| D1117A | 11.3 | 17.0 | 3 | 13.5 | 6 | 18 | 1.2 |

| D1218A | 12.35 | 18.0 | 3 | 12 | 6.5 | 18 | 1.5 |

| D1319A | 13.35 | 19.0 | 3.5 | 13.5 | 7.1 | 18 | 1.5 |

| D1420A | 14.35 | 20.0 | 4.2 | 13 | 8 | 18 | 8 |

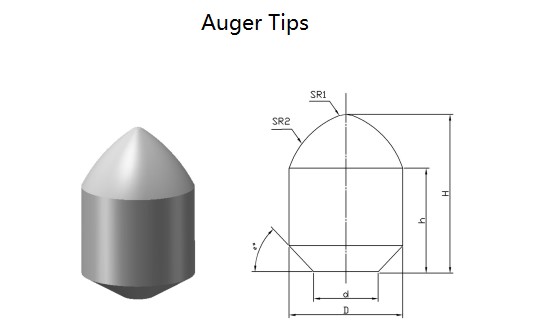

| Type | Dimension(mm) | |||||

| D | d | H | h | SR1 | SR2 | |

| JM1222 | 12 | 3.0 | 22 | 15 | 1.5 | 26 |

| JM1425 | 14 | 4.0 | 25 | 17 | 1.5 | 26 |

| JM1625 | 16 | 5.0 | 25 | 16 | 1.5 | 26 |

| JM1828 | 18 | 5.0 | 28 | 18 | 1.5 | 26 |

| JM2428 | 24 | 10.1 | 28 | 16 | 2 | 36 |

| JM2534 | 25 | 18.0 | 34 | 20 | - | 25 |

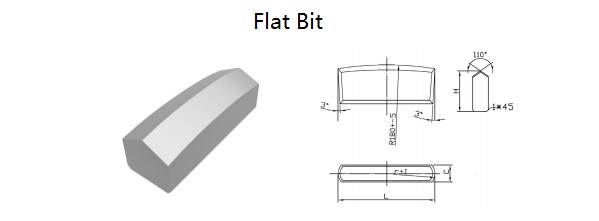

| Type | Dimension(mm) | |||||

| L | H | C | r | |||

| A | B | C | ||||

| K026 | 26 | 18.0 | 15 | 12.5 | 8 | 13 |

| K028 | 28 | 18.0 | 15 | 12.5 | 8 | 14 |

| K030 | 30 | 18.0 | 15 | 12.5 | 8 | 15 |

| K032 | 32 | 18.0 | 15 | 12.5 | 8 | 16 |

| K034 | 34 | 18.0 | 15 | 12.5 | 8 | 17 |

| K036 | 36 | 18.0 | 15 | 12.5 | 10 | 18 |

| K038 | 38 | 18.0 | 15 | 12.5 | 10 | 19 |

| K040 | 40 | 18.0 | 15 | 12.5 | 10 | 20 |

| K042 | 42 | 18.0 | 15 | 12.5 | 10 | 21 |

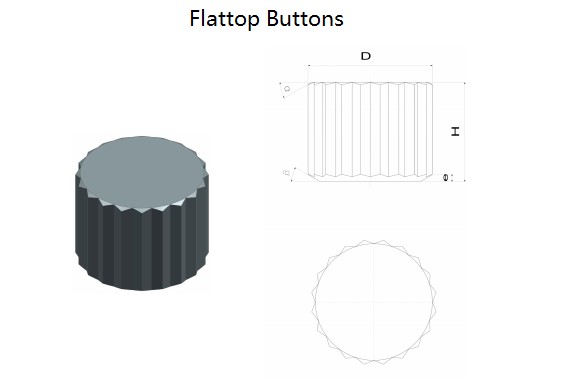

| Type | Dimension(mm) | ||||

| D | H | t | α° | e | |

| MH0806 | 8 | 6.0 | 0.5 | 25 | 1.1 |

| MH1008 | 10 | 8.0 | 0.5 | 25 | 1.9 |

| MH1206 | 12 | 6.0 | 0.5 | 25 | 1.9 |

| MH1208 | 12 | 8.0 | 0.5 | 25 | 2.5 |

| MH1410 | 14 | 10.0 | 0.5 | 25 | 2.5 |

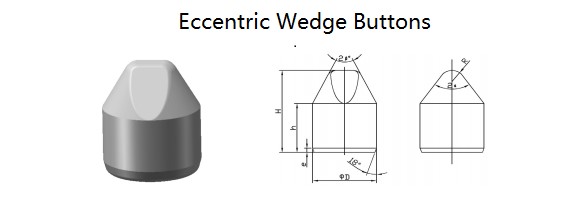

| Type | Dimension(mm) | |||||||

| D | H | h | R | r | α° | β° | e | |

| X0810 | 8 | 10 | 6.5 | 2 | 1.8 | 45 | 22.5 | 1.5 |

| X1011 | 10 | 11 | 7 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1013 | 10 | 13 | 9 | 2.5 | 2 | 45 | 22.5 | 1.5 |

| X1115 | 11 | 15 | 8 | 2.8 | 2.5 | 22.5 | 22.5 | 1.5 |

| X1215 | 12 | 15 | 9 | 3 | 2.5 | 45 | 22.5 | 1.5 |

| X1217 | 12 | 17 | 10.5 | 3.5 | 3 | 35 | 20 | 1.5 |

| X1418 | 14 | 18 | 10 | 3.5 | 3 | 45 | 22.5 | 1.5 |

| X1420 | 14 | 20 | 11 | 2.7 | 3 | 35 | 22.5 | 1.5 |

| X1520 | 15 | 20 | 12 | 3 | 3 | 40 | 22.5 | 1.5 |

| X1621 | 16 | 21 | 11 | 2.6 | 3 | 35 | 22.5 | 2 |

| X1623 | 16 | 23 | 12 | 3 | 3.5 | 30 | 18 | 2 |

| X1721 | 17 | 21 | 13 | 4 | 3.5 | 40 | 22.5 | 2 |

| X1724 | 17 | 24 | 13 | 3.5 | 3.5 | 30 | 22.5 | 2 |

| X1929 | 19 | 29 | 17 | 4 | 3 | 30 | 15 | 2 |

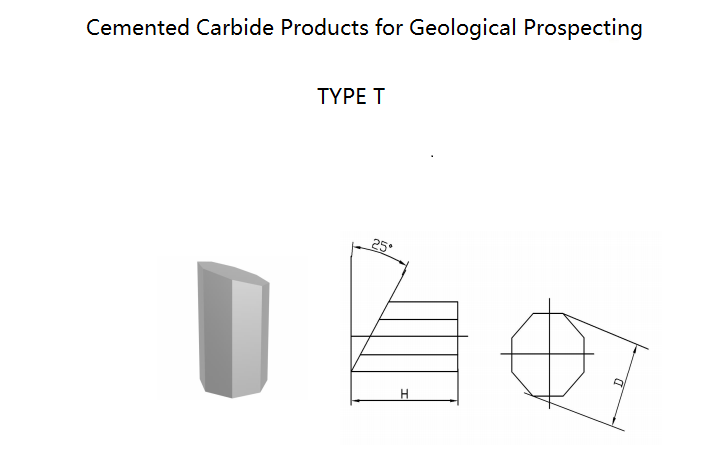

| Type | Dimension(mm) | |

| D | H | |

| T105 | 5 | 10 |

| T106 | 7 | 10 |

| T107 | 7 | 15 |

| T109 | 9 | 12 |

| T110 | 10 | 16 |

Our Advantages

The cemented carbide button has superior wear resistance and impact toughness, and has higher drilling speed than similar products. The non-grinding life of the bit is about 5-6 times as long as that of the bit with the same diameter, which is beneficial to saving auxiliary working hours, reducing manual labor and speeding up engineering speed.

For more detail, welcome to contact us in anytime!

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope