Tungsten Carbide Vacuum Grinding Jar

Description

Ball mill grinding jar is mainly used in laboratories, research centers and enterprises to grind experimental samples or production raw materials, and at the same time mix, disperse and normalize ultra-fine powder processing equipment. Its multi-function, small size, high efficiency, low energy consumption, safe and stable, simple operation, can be seen in many industries such as minerals, chemicals, building materials, medicine, electronics, etc.

The laboratory jar mill usually with 4 carbide grinding jars, it is a high-speed movement, the materials are processed by squeezing, impacting and grinding the materials sealed in the cemented carbide ball mill jars, which can be dry grinding, wet grinding, low temperature grinding, vacuum grinding... It is currently the most popular ultra-fine powder processing equipment.

Why choose tungsten carbide material to make grinding jar?

Although planetary ball mill is powerful and capable,tungsten carbide grinding jar is indispensable. The grinding and mixing process is carried out in the carbide ball mill jar, because the carbide ball mill jar is required to have a good seal,dry and wet grinding can be carried out. So high-quality carbide ball grinding jar is the best choice.

Application

Carbide ball mill grinding jar is used in planetary ball mill, with carbide grinding ball, used for grinding carbide powder, diamond, diamond and other high hardness powder.

Future Of Tungsten Carbide Grinding Jar

1 .High temperature resistance, operating temperature can reach to 1000 ° C.

2 .High wear resistance at 500 °C.

3 .High hardness, ultra-high hardness is the main characteristics of cemented carbide grinding jars.

4 .Strength and toughness, not only has the high hardness, but also has the very good toughness.

Normal Specifications

| Volume(ml) | H(mm) | OD(mm) | ID(mm) | Lip T(mm) | Wall T(mm) |

| 50 | 61.5 | 48 | 36 | 8 | 6 |

| 100 | 59 | 63 | 51 | 6 | 6 |

| 250 | 69 | 86 | 74 | 10 | 6 |

| 500 | 96 | 105 | 92 | 14 | 6.5 |

| 1000 | 125 | 130 | 115 | 14 | 7.5 |

Other Products You May Like

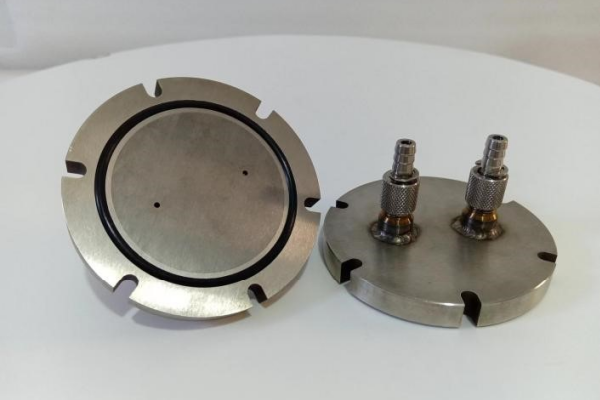

There are several types of carbide grinding jars’ photos as below:

Our Advantages

● We are a factory with more than 15 years experience.

● OEM and ODM are acceptable.

● Samples will be sent within 3 working days if available in stock.

● Small trial order is accepted at initial cooperation.

● Material expertise for demanding challenges

● From lab research to batch production

● Multi-axial press capabilities

● All molds made in-house

● HIP sintered

● Quick delivery 4~6 weeks

More details, welcome to contact us in anytime!

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope