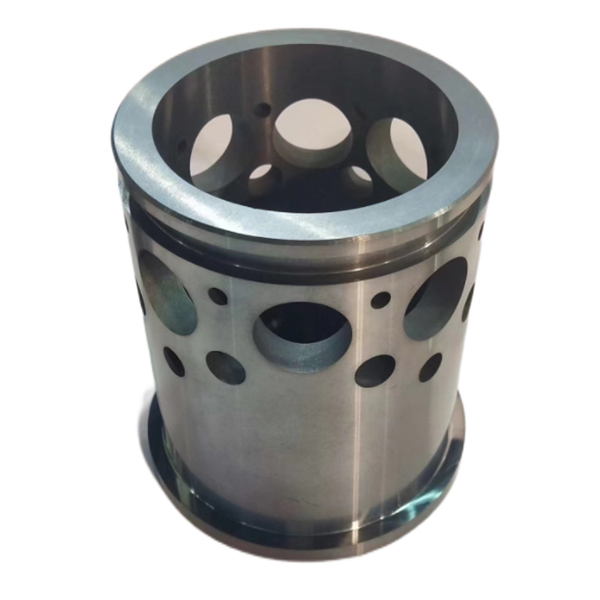

Wear Resistant Tungsten Carbide Valve Cage For Wellhead Tools

Description

The tungsten carbide cages are widely used in the valves to control the fluid volume and pressure accurately. The most popular grade for cemented carbide cages are CR05A and CR06N, which have performed well in application of valves. The size of the product is controlled accurately and the position of the hole is accurate to meet the requirements of the valve in use.

Carbide flow control cage for wellhead blowout preventer in the construction of oil and natural gas drilling, in order to safely drill through high-pressure oil and gas formations and avoid the occurrence of out-of-control drilling blowout accidents, it is necessary to install a set of equipment—drilling well control device.

The products and technologies from Zhuzhou Chuangrui have been widely applied in the fields of oil & gas, chemical engineering, subsea, nuclear power and aerospace industries. Mainly used in harsh operating conditions include severe abrasion, erosion, corrosion, high temperature, high pressure and strong impact. Our major clients are Fortune 500 companies. Zhuzhou Chuangrui is the leading export enterprise in China of wear-resistant cemented carbide products and the related high-precision machining techniques.

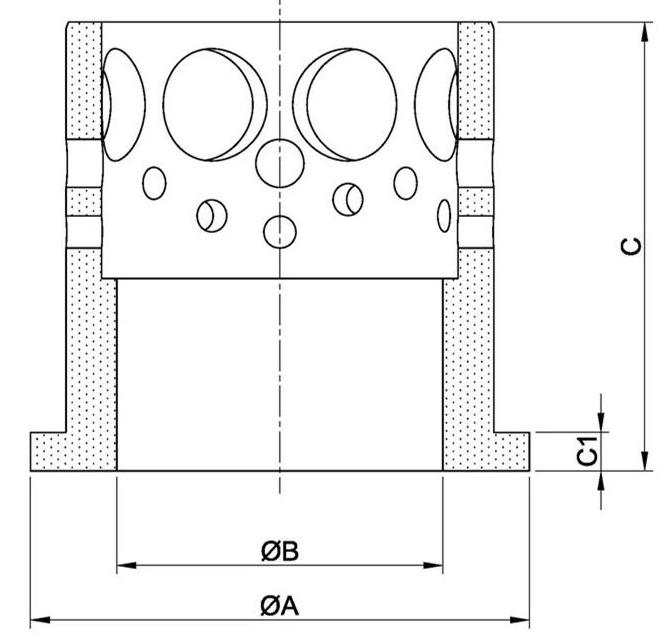

Structures

Zhuzhou Chuangrui Cemented carbide wear parts have a variety of specifications, processed and made with high quality raw material. It has the characteristics of high temperature resistance, corrosion resistance, abrasion resistance, erosion resistance, high precision and so on.We are manufacturing tungsten Carbide wear parts for use Oil & Gas Industry. Zhuzhou Chuangrui cemented carbide wear parts are available in a wide range of styles and size combinations for arduous application.The valve cage has four typical structures:

Advantage

● With ASP9100 certificate , API certificate, ISO9001:2015.

● With a Special Thread Processing Workshop.

● Consistent High Quality, long lifespan circle.100% Virgin Material.

● Customized as your requirements.All mold made in-house.

● Approved factory for oil and natural gas industry TOP10 customers.

|

ΦA |

ΦB |

C |

|

70.8 |

50.8 |

104 |

|

95.3 |

76.2 |

111 |

|

155.5 |

101.6 |

140 |

The material information of grade as follows:

| Grades | Physical Properties | Major application and characteristics | ||

| Hardness | Density | TRS | ||

| HRA | g/cm3 | N/mm2 | ||

| CR05A | 92.0-93.0 | 14.80-15.00 | ≥2850 | It is suitable to produce wear parts used for oil-immersed pump, valve point and valve seat due to excellent wear resistance and high toughness |

| CR06N | 90.2-91.2 | 14.80-15.00 | ≥2650 | It is suitable to produce sleeves and bushings used in oil & gas industry due to excellent corrosion & erosion resistance |

Representative Products Line

● Chokes and valves trim parts

● Pumps seal rings

● Drill bit nozzles, inserts, cutters

● MWD parts, downhole tool components

● TC bearings, PDC thrust bearings

● Downhole flow control components

● Artificial lift pumps components

Production Equipment

Wet Grinding

Spray Drying

Press

TPA Press

Semi-Press

HIP Sintering

Processing Equipment

Drilling

Wire Cutting

Vertical Grinding

Universal Grinding

Plane Grinding

CNC Milling Machine

Inspection Instrument

Hardness Meter

Planimeter

Quadratic Element Measurement

Cobalt Magnetic Instrument

Metallographic Microscope